CIDAN PRO FOLDING MACHINE

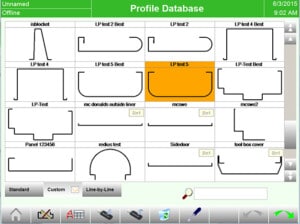

ProLink Control System

Our ProLink software offers easy and local programming, helping you add more functionality to your metal forming production. Take your programming to the next level with the convenience and efficiency of automation.

Advantages of the ProLink Control System

- Automatic folding and collision detection

- Machine to profile interfacing

- Remote offline programming

- Adjustable and flexible touch screen

Height Adjustable Back Gauge

The back gauge table is often the single most important item when investing in a power folder. It can save businesses time and money if the system is flexible and fully incorporated with a control system. PRO is as standard delivered with a height adjustable back gauge. The CNC control ProLink guarantees that the back gauge table automatically adjusts and moves when you reach the next step in the sequence. Height adjustable back gauge requires multifold execution.

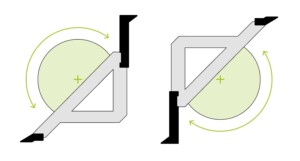

Multifold Tooling

Divided tooling for maximum flexibility in every situation! With our optional multifold execution, the lower beam and folding beam tools are segmented. Segmented tools are used when the details should be folded on more than two sides and in different directions. Segmented tools are also used to bend only sections of the detail.

Almost all models can be equipped with Multifold. Multifold can only be supplied with Combi beam.

Advantages of Multifold Tooling

- Enables high precision metal forming and bending

- Capable of bending parts with interrupted bend lines

- Add unlimited complicated details to your production

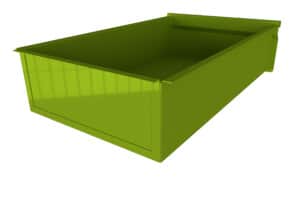

Combi Beam Tool Changer

The optional Combi beam offers flexibility like no other tooling system. With a simple rotation of the upper beam, you can switch between the straight rail and box tooling in a matter of seconds. This gives the ability to form a larger variety of parts with little or no tool changing.

Advantages of the Combi beam

- Quick tool changes

- Large space around the tools

- Increased flexibility

- Same opening height regardless of tool selection

CIDAN PRO folding machine is our most versatile machine yet. From the integrated back gauge, allowing complex parts production from the folding side, to the Combi beam with its high divided tools and straight rail, the CIDAN PRO folding machine takes many of our additional options and makes them standard. With its 100% duty cycle of forming 4 mm at 3100 mm, this fully upgraded metal folder makes it possible to replace two operators with one and still produce accurate parts up to four times faster than with a press brake.

- Dual drive of clamping beam gives incredible speed and accuracy. The turbo drive also increases hemming capacity to 50 tons (55US).

- Combi beam with high divided tools and straight rail in combination with segmented tools in the lower beam and folding beam can facilitate extremely complicated folding work.

- Automatic folding beam crowning and automatic sheet thickness adjustment for precise folding.

- With high speed and extreme accuracy of the back gauge, exact measuring is ensured and with turbo driven folding beam you will get the right folding angle every time.

- Height adjustable back gauge table a as standard.

| Specifications | ||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Folding length | Folding capacity | Opening height | Outer dimensions | Weight | Motors | ||||||||||||||||||||||||||||||||||||||||||||

| mm (“) | Steel mm (ga) | Stainless Steel mm (ga) | Aluminum mm (“) | Clamping beam mm (“) |

Length x Width x Height mm (“) | kg (lbs) | Clamping beam kW (hp) |

Folding beam kW (hp) |

||||||||||||||||||||||||||||||||||||||||||

| PRO 30 Multifold | 3100 (122) | 4 (9) | 2.5 (13) | 6 (0.236) | 200 (7.88) | 4392 (173) x 2539 (100) x 2085 (82) | 8130(17886) | 4 (5.5) | 5.5 (7.5) | |||||||||||||||||||||||||||||||||||||||||

| PRO 40 Multifold | 4100 (161) | 3 (11) | 1.9 (15) | 4.5 (0.177) | 200 (7.88) | 5392 (212) x 2539 (100) x 2085 (82) | 10500 (23100) | 4 (5.5) | 5.5 (7.5) | |||||||||||||||||||||||||||||||||||||||||

- Combi beam equipped with quick change box tooling

- ProLink W control, with 18.5″ touch screen and graphic programming

- Multifold System – Segmented lower and folding beam tooling

- Height adjustable back gauge

- CNC material thickness adjustment (0-.157″) and manual from (.157″-.787″)

- Tooling is made from 42CrMo4 steel, and coated with black oxide to prevent rust

- CNC controlled crowning of folding beam rail.

- Material thickness sensing on clamping beam

- Eccentric clamping deam drive -55 tons clamping pressure

- Speed optimization – when folding beam comes down to 80 degrees, upper beam starts to come up

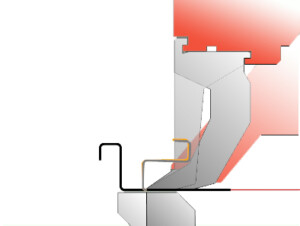

High divided tools 152 mm or 254 mm /6 or 10″ height with quick change looking system, high divided tools 152 mm / 6″ in C shape.

152 mm high divided C-shaped tools. With C-shaped tools you can fold deeper profiles than with standard tools or straight rail.

Hardened tooling for 100% stainless application (HRC 45).

For large applications like panels, doors and cabinets, we recommend a J-shaped or U-shaped back gauge. With the expandable back gauge table, the operator can choose to work either at the folding or gauging side of the machine. Even 3 and 4 m parts can easily be handled by one operator.

Motorized back gauge SBG with twice the amount of ball transfers as standard. SBG back gauge is equipped with ball screw, linear guides and servo motor for highest precision and repeatability. The back gauge speed enables the productivity to increase and at the same time, decreases the costs of your forming operation. Front stop units are made of spring steel as standard, solid front stop units are optional. The stop units can be dropped down automatically in every program row, which prevents any collision with the stop units when the sheet needs to be rotated. Back gauge panels can be moved backwards when folded details requires free space behind the lower beam tool.

Our robust back gauge system SBG is equipped with height adjustment (0 – 50 mm) as standard for PRO machines. This is perfect for gauging reverse z-flanges on the back gauge.

Makes positioning of large and narrow parts easier. Available in three lengths 1000 mm (39.3″), 1500 mm (59″) and 3000 mm (118″) for left and/or right hand side.

21.5 “widescreen instead of 18.5” to ProLink W.

With the offline-software option on ProLink W, programming can be completed in the office away from the machine.

The safety scanner provides extra safety with two modes when operating machine from folding side or gauging side. The scanner prohibits any person to enter the working area where a collision with the folding beam is possible.

Add the optional safety bumper for a safer working environment.

6 outputs for ProLink.

Safely store the divided tooling for your CIDAN folder. The tool cart is recommended to decrease the risk of damaging tools and misplacing tools during tool changing. It is possible to store divided rails on the cart and there is room for hand tools for the operators and machine instruction manual. The cart is equipped with lockable wheels and pull handles. Especially recommended if the machine is equipped with the Multifold tooling system.

Ball transfers on the back gauge assist with the positioning of larger, heavier parts and reduce the risk of scratching the material.

Allows the operator to move the foot pedal quickly and smoothly along the folding area. Appropriate when folding is done with several folding stations. Especially recommended if the machine is equipped with Multifold. This option is considered a great safety feature when bolted to the floor. When operator engages foot pedal, they are away from the upcoming folding beam.

Turnable, solid front fingers in spring steel on back gauge.

Extra foot pedal available for rear operation.