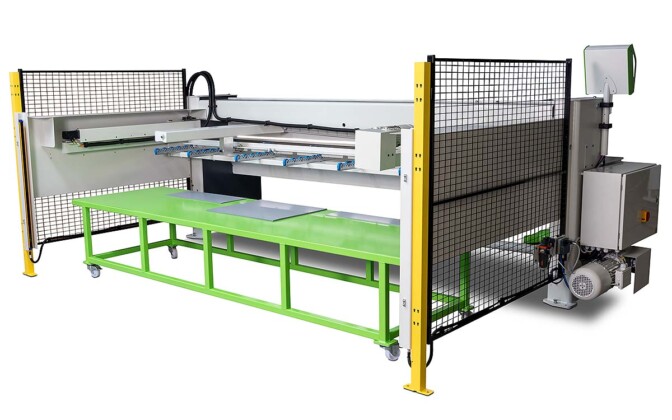

Products RAPIDO SSM Stacking Sensitive Material

RAPIDO SSM Stacking Sensitive Material

CIDAN RAPIDO SSM (Stacking Sensitive Material) is our cut n’ stack system that speeds up your guillotine shear and never leaves you with scratches or dog-ears.

Set backgauge measurements and number of cuts. The sheet support is pulled back fast as lightening and the cut material falls gently down onto the moveable material wagon (option) where the sheets are stacked at a speed of up to 24 panels per minute. The material wagon can be loaded with up to 700 kg. If you cut widths of 125-410 mm you can stack to a height of 90 mm, with widths more than 410 mm, to a height of 40 mm.

In combination with the CutLink control system you have a real cutting and stacking giant that can be programmed for different backgauge settings in the desired quantities, all with neat stacking on the material wagon. There is no smarter, gentler or more efficient backgauge system for high volumes.

- Shear can cut all material qualities – mild steel from 0,4 mm (28 gauge) up to 2,5 mm (13 gauge) without any settings at all and the blade gap stays the same.

- Fully mechanical, electrical, no use of oil – not hydraulic.

- Drive system with eccentrics and pulldown rod connected to the upper blade beam.

- Material is clamped between the table and the hold down beam, with a rubber strip to protect sensitive material from getting marks.

- Standard squaring arm and table extension (option).

- CutLink touch control for single or automatic mode.

| Specifications | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Working length | Material thickness | Speed | Weight | |||||||||||||||||||||||||||||||||||||||||||||

| mm (“) | Steel mm (ga) | Stainless Steel mm (ga) | Aluminum mm(“) | Cuts/min | kg lbs) | ||||||||||||||||||||||||||||||||||||||||||||

| RAPIDO 32 SSM | 3200 (126) | 2.50 (13) | 1.6 (16) | 3.7 (0.145) | 24* | 2100 (4630) | |||||||||||||||||||||||||||||||||||||||||||

| RAPIDO 41 SSM | 4100 (161) | 1.50 (16) | 0.6 (24) | 2.2 (0.08) | 24* | 2500 (5511) | |||||||||||||||||||||||||||||||||||||||||||

*when cutting 125 mm, 15 cuts/min when cutting 750 mm, 35 cuts/min when cutting 0-100 mm but without SSM-function

OPTION

| Specifications | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Max load | Working width | Stacking height sheet width |

Stacking height sheet width |

|||||||||||||||||||||||||||||||||||||||||||||

| kg | Length mm | Width mm | Height mm | 125-410 mm | 410-1000 mm | ||||||||||||||||||||||||||||||||||||||||||||

| Material wagon 32 | 700 | 3000 | 800 | 560 | 90 | 40 | |||||||||||||||||||||||||||||||||||||||||||

| Material wagon 41 | 700 | 4010 | 800 | 560 | 90 | 40 | |||||||||||||||||||||||||||||||||||||||||||

- 1000 mm motorized backgauge with CutLink touch control

- Single or continuous stroke control

- Double edged blades

- LED cutting line light

- Finger protection

- Squaring arms on both sides, 380 mm with scale

- Table with scored measuring lines

- Pneumatic hold down beam

- Button to start the cut at the electrical cabinet

- Foot pedal to start cut

- Sheet support CNC controlled

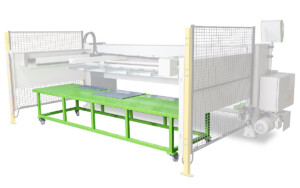

Movable material wagon on wheels that can withstand a load of 700 kg. Easily move cut and neatly stacked material to another workstation. It is also possible to order extra material wagons.

The moveable material wagon is offered as an alternative to fixed return plate for return to sender option. Easily move cut material to another workstation with this option. Plus, it can be picked up with a forklift. Features include: lockable wheels and removable handle.

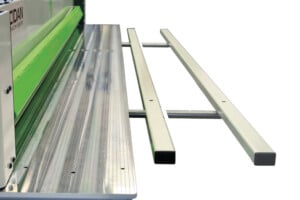

Squaring arm with or without T-groove and tilt stop. Available in lengths of 1000 mm and 2500 mm for RAPIDO.

Extendable table extension for RAPIDO, 800 mm (option).

Forced cooling of the cuttingmotor for continuous high volume cutting