TC DOUBLE FOLDER

Integrated flipping device

Significant reduction of part handling by operators at the machine is achieved through an integrated flipping device that automatically turns parts. Parts are flipped automatically and subsequently placed accurately by the gripper units for the next bend.

The additional benefits are multiple: the operation is faster, it is safer for operators, it improves accuracy and it increases capacity at reduced costs.

In combination with the integrated sheet loading device CIDAN offers a fully automated solution for the folding operation. Operator activity is limited to loading a stack of sheets in a feeder and discharge bended parts from the machine.

Side loading device

The automated integrated side loading equipment mounted on a folder provides significant efficiency gains and operational cost reductions. The only operation required at a machine with automated side loading is to keep the feeder filled with sheet metal and turn or unload the folded sheet-metal parts. Reduction of labour time at the machine is significant. With the automated sideloading device multiple parts can be loaded and folded at the same time.

The loading table with a high load capacity is mobile, can be automatically adjusted in height and can be supplied in different lengths. Optionally, the sheets are automatically made available in single feed, from a stack or directly from an upstream de-coiler.

The additional benefits are multiple: the operation is faster, safer for operators and can be integrated on the operations with minimal need for extra floor space. The integrated sheet loading device improves accuracy and increase capacity at reduced costs.

In combination with the integrated flipping device CIDAN offers a fully automated solution for the folding operation. Operator activity is limited to loading a stack of sheets in a feeder and discharge bended parts from the machine.

The kinetic Torsion shaft technology provides maximal precision and reproducibility of folded parts. This technology is unmatched and unique to all THALMANN folders.

The synchronized distribution of force to the machine is at the heart of all THALMANN machines and can be compared to the synchronised mechanical control used in aircrafts. No other folder in the market is capable to deliver folded parts with an accuracy delivered through this technology.

A curved lower clamping beam allows more freedom and possibilities in the production of sheet metal profiles. The free space is extended through the folder cropped beam dimension. The additional space allows for bends with a 1:2 aspect ratio.

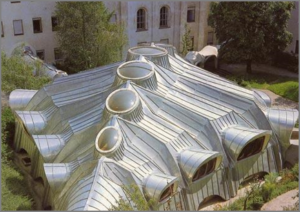

Architects, industrial designers and façade designers are continuously looking for new profile geometries. With the addition of a cropped bending beam on a THALMANN folder a wider range of dimensions of bended sheet metal parts can be produced. With this feature THALMANN customers are able to expand their product portfolio and business for folded sheet metal parts.

Modular and interchangeable hemming and roll forming units extend possibilities of forming sheet metals on a THALMANN machine. The hemming and roll forming unit can be mounted directly on the THALMANN long folding machine. This unit is ideal for the production of calibrated highly accurate dimension panels and very tight hems.

In addition to achieving operational efficiencies trough the integration of folding and a hemming and roll former unit in one operation, the folded metal sheets are less prone to damaging due to the reduction of manual handling. Scratches or bumps will be avoided with an electrical slitter unit.

On one and the same guiding system slitters and hemming/roll former heads are interchangeable. Both reductions in costs and investments are clear benefits and can be retrofitted on an existing THALMANN machine.

The TC Double Folder is often affectionately and respectfully referred to as “Big Mama” – due in large part to its solid construction. Of the 11,564 hand-crafted, high-quality parts that make up this double folder, the five 50 mm torsion drive shafts on the folding and upper beam movement give this machine its reputation of accuracy and longevity. Like the TD, the accuracy of the “Big Mama” is derived from the rotary encoders application directly on the torsion shaft. The torsion drive shafts completely eradicate the “twisting” that generally occurs over time. That means the TC metal double folder will produce a 60-bend part with an incredible end to end deviation of 2 mm!

Benefits

- Increased bending accuracy and additional free bending space

- Reduction of processing costs and increased capacity utilisation

- Higher throughputs and increased capacity

- Faster bending speeds and more flexibility

- Better part quality and reduction of costs per bended part

- Lean manufacturing processes and increased safety

- Access to new markets and competitive advantages

- Minimal maintenance requirements and longevity of machines

- Integrated automated solutions and open interfaces

Typical applications for long folders

| SPECIFICATIONS | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TC300 | |||||||||||||||||||||||||||||||||||||||||||||||||

| Model | TC300 4.2 | TC300 6.4 | TC300 8.2 | TC300 10 | TC300 12 | ||||||||||||||||||||||||||||||||||||||||||||

| Gauge Capacity | 3.0 mm | 3.0 mm | 3.0 mm | 3.0 mm | 3.0 mm | ||||||||||||||||||||||||||||||||||||||||||||

| Bending Length | 4 m | 6.4 m | 8 m | 10 m | 12 m | ||||||||||||||||||||||||||||||||||||||||||||

| Backgauge Depth | 1250 mm | 1250 mm | 1250 mm | 1250 mm | 1250 mm | ||||||||||||||||||||||||||||||||||||||||||||

| Folding Accuracy | ± 0.5° | ± 0.5° | ± 0.5° | ± 0.5° | ± 0.5° | ||||||||||||||||||||||||||||||||||||||||||||

| Folding Range | 140° | 140° | 140° | 140° | 140° | ||||||||||||||||||||||||||||||||||||||||||||

| Folding Beam Width | 12 mm | 12 mm | 12 mm | 12 mm | 12 mm | ||||||||||||||||||||||||||||||||||||||||||||

| Number of Grippers | 4 | 5 | 7 | 9 | 11 | ||||||||||||||||||||||||||||||||||||||||||||

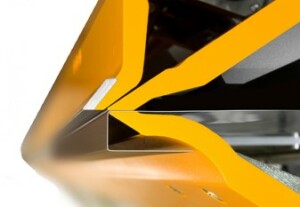

As standard, a straight lower-beam tool with a very flat angle of inclination of just 35° is supplied. This allows the manufacturing of profiles with an aspect ratio of 3:4 (ratio of height to depth). A curved lower-beam tool, resembling a goat’s foot, can be optionally supplied. This tool can be used to shape parts with an aspect ratio of 1:2 (e.g. 1.5 inches height and 3 inches of depth). This results in significantly more space available and an increased clearance of totally 275°, providing key flexibility when folding.

To increase the scope of product dimensions that can be folded on a THALMANN machine, a wide range of gripper designs can be selected. Spring-loaded fingers are automatically activated to position the sheet metal in the right place when the smallest possible gripper measurement is exceeded.

Significant cost reductions and efficiencies can be obtained through high speed of folding cycles which is guaranteed by the simultaneous movement of several machine axes. This innovation has been designed to speed up cycles without any loss of folding dynamics and accuracy. Dynamic Folding Technology (DFT) is the basis of increasing productivity and capacity utilization of the folding operation. The technology of simultaneous movements ensures a minimum of stop times in a bending cycle.

The kinetic Torsion shaft technology provides maximal precision and reproducibility of folded parts. This technology is unmatched and unique to all THALMANN folders. The synchronized distribution of force to the machine is at the heart of all THALMANN machines and can be compared to the synchronized mechanical control used in aircraft. No other folder in the market is capable to deliver folded parts with accuracy delivered through this technology.

For efficient remote service, THALMANN comes with the ability to access the control through TeamViewer. Remote maintenance offers the possibility to quickly help with application and also troubleshoot.

Precisely formed profiles with even angles over the entire length is what you expect from a good folding machine. The crowing system and dial indicators allow this operation to be adjusted quickly and accurately. Thalmann’s are known for not having to adjust crowning for most profiles, but when in need this innovation compensates for angular deviations.

High performance 10-axis PC from Beckhoff with 21,5” multi-touch 16:9 widescreen panel. The TD’s DS3000 software includes the ability for, Manual, semi-automatic and automatic operation, Sketch programming and profile auto sequencing, Bending simulation with collision display, Graphical visualization of profiles in 3D, Interface to DXF data format,as well as nuIT, Stand-alone software for PC and laptop programming.

The ability to fold parts down to 200 mm can be achieved by selecting double gripper units on a THALMANN machine. Each existing single gripper can be made into a double gripper unit by “adding” an additional gripper.

A fully automatically activated spring loaded finger can be placed left or right or both sides of the double gripper unit.

The production of tapered parts is possible up to dimensional offset of +/- 250 mm. The positioning of the sheet metal is fully automated and multiple sheets can be manufactured in a tapered shape at the same time on one machine.

With the option of an automated tapered back-gauge, architects, roofers and engineers have the possibility to develop novel profile geometries and extend the scope of façade design.

A wide range from 5 mm up to 1150 mm sheets can be folded with high accuracy with the installation of automated back gauge stop fingers on the THALMANN machines.

Back gauge stop-fingers will automatically be activated when the smallest possible grip zone is exceeded. The back gauge stop fingers will position the sheet metal in the right place.

Mounted on the bending beam, a selection of different interchangeable beam extensions can greatly extend the scope of bends produced on a THALMANN machine.

To improve durability and for heavy duty bending operations, HARDOX 400 steel bending beams will greatly enhance tool life as well as maintain accuracy of folded parts. The type of steel used to produce the beams is similar to the steel used for excavator shovels.

The extremely wear resistant Hardox beams will under normal operation last the lifetime of the machine and can be welded when damaged. Hardox beams on a THALMANN machine improves the stiffness and stability of the machine.

Companies that apply additional cutting of folded sheets can integrate this operation on the THALMANN machine by adding a fully automated slitter unit. Investment in additional dedicated cutting or de-coiler units can often be avoided selecting this machine option.

In addition to achieving operational efficiencies trough the integration of folding and slitting in one operation, the folded metal sheets are less prone to damaging due to the reduction of manual handling. Scratches or bumps will be avoided with an electrical slitter unit.

On one and the same guiding system slitters and hemming/roll former heads are interchangeable. Both reductions in costs and investments are clear benefits and can be retrofitted on an existing THALMANN machine.

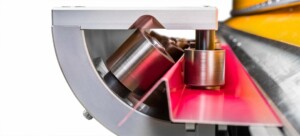

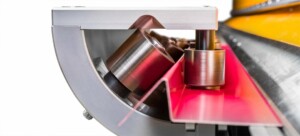

Modular and interchangeable hemming and roll forming units extend possibilities of forming sheet metals on a THALMANN machine. The hemming and roll forming unit can be mounted directly on the long folding machine. This unit is ideal for the production of calibrated highly accurate dimension panels and very tight hems.

In addition to achieving operational efficiencies trough the integration of folding and a hemming and roll former unit in one operation, the folded metal sheets are less prone to damaging due to the reduction of manual handling. Scratches or bumps will be avoided with an electrical slitter unit.

On one and the same guiding system slitters and hemming/roll former heads are interchangeable. Both reductions in costs and investments are clear benefits and can be retrofitted on an existing THALMANN machine.

For an efficient and extended scope of remote service, the optional M-Guard functionality is recommended. A secure and fast direct link between a THALMANN machine anywhere in the world and the service team in Switzerland is easily established with M-Guard.

M-Guard offers the possibility to perform software updates, software diagnostics and problem solving tasks. Up- to-date VPN technology ensures safe and fast data-transfer. Remote maintenance significantly reduces costs and time as no travel will be required to deliver this service.

As standard, a straight lower-beam tool with a very flat angle of inclination of just 35° is supplied. This allows the manufacturing of profiles with an aspect ratio of 3:4 (ratio of height to depth). A curved lower-beam tool, resembling a goat’s foot, can be optionally supplied. This tool can be used to shape parts with an aspect ratio of 1:2 (e.g. 1.5 inches height and 3 inches of depth). This results in significantly more space available and an increased clearance of totally 275°, providing key flexibility when folding.

Architects, industrial designers, and facade designers are continuously looking for new profile geometries. With the addition of a cropped bending beam on a THALMANN folder, a wider range of dimensions of bended sheet metal parts can be produced. With this feature, THALMANN customers are able to expand their product portfolio and business for folded sheet metal parts.

Efficiencies, process flexibilities can be significantly enhanced by folding several sheets at the same time within one folding cycle. The THALMANN machines can be custom equipped with fully automated multi section grippers that allows to handle and process several parts at the same time by one operator. For example 2 x 3 meter sheets can be folded simultaneously by one operator on a 6.4 meter Thalmann TD folder.

High-performance hydraulics with oil cooler. The unit with depressurized circulation principle guarantees low energy consumption and low noise level.