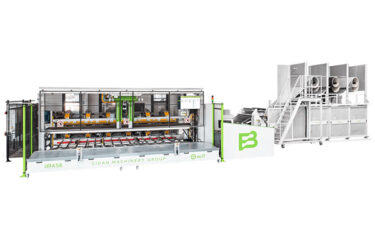

Fully automated lines

Customer benefits

-

Fully automatic

Automated Production line for metal trims/metal profiles & automated Labeling with profile data and individual notes.

-

Small space

Full integration of Coil line, Bending machine, parts handling within small space.

-

More flexibility

Real time Cutting optimization – step cuts for even more flexibility.

-

Individual

From batch size 1 to serial production.

-

One operator

Operation of the whole line with just a single person – coil handling, cutting, bending, labeling, packaging. Coil line and bending machine also usable in semi automated and manual mode.

-

Full integration

With the use of the nuIT Software packages The BASE can be integrated into all company processes and areas – ordering, work and production planning, production, logistics, ERPintegration…

The BASE Standard

From coil to finished trim without human touch.

All automated!

The BASE+ Punching

The standard feature plus a large variation on different punched profiles.

Read about the BASE Punching line

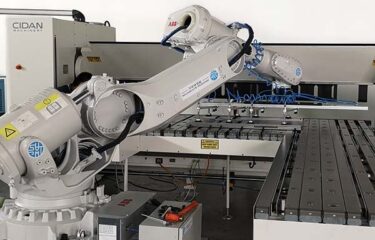

CIDAN Automation interfaces

By adding a robot interface to any of our folding machines with a Prolink control panel the machine will be ready for integration with a robot for full automation.

Read about our Automation interfaces