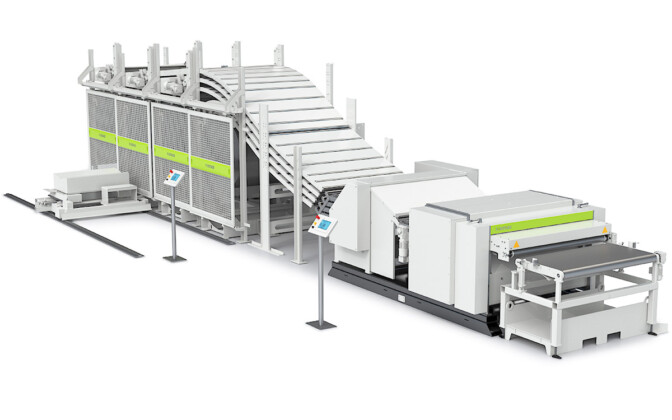

Feeding Line

Our multiple coil system will not mark the sheet metal and provides fully automatic changeover from one decoiler to another in less than one minute.

Thanks to Forstner’s advanced technology for straightening of sheet metal, undesired stop marks is avoided. Automatic changeover has been standard for decades.

Smart sheet metal technology means you can keep lower stocks, free up tied capital, shorten lead times and increase efficiency. Our decoiler lines are demand-driven and process the right material in the right order, at the speed and the precision you want. Just start up the program and the sheet metal is fed in, straightened, measured and cut to the correct dimensions ready for the next step. A straight-through process, the material is fed directly into the panel bender, punching machine, laser cutter or whatever machine you choose. The coil line is controlled via CSV-files from your work order and the process is completely automated with no operator input whatsoever. Lead times are shortened and you automatically get the right material in the right order so you can utilize waiting machines at maximum capacity.

Get up to speed, lower your waste and get perfect flat panels for further processing with Forstner decoiler lines.

Efficient production of sheet metal requires access to a wide range of different coils. To enable quick access to various coils, we developed a production line that can hold up to six coils. Our multiple coil system is very gentle to the material and offers fully automatic shifting from one decoiler to another in less than a minute.

The most important advantages:

- Covers the major part of your material requirements.

- Fully automated material changes in less than one minute.

- Easy control with CSV files.

- Single operator.

- Easily integrated with other production machinery.

- High speed, sharp, quality and precision.

- Reduces waste with the help of

step cut.

Forstner feeding line with decoiling, straightening, slitting and and cutting offers features that a production manager could only dream of.

| Specifications | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Feeding Line | |||||||||||||||||||||||||||||||||||||||||||||||||

| Features | Values | ||||||||||||||||||||||||||||||||||||||||||||||||

| Max number of coils | 6 pcs | ||||||||||||||||||||||||||||||||||||||||||||||||

| Max weight per coil | 7 ton | ||||||||||||||||||||||||||||||||||||||||||||||||

| Max sheet thickness (steel)* | 1.0 mm | ||||||||||||||||||||||||||||||||||||||||||||||||

| Max sheet thickness (stainless steel)** | 0.85 mm | ||||||||||||||||||||||||||||||||||||||||||||||||

*Max sheet thickness (steel) width pre-bending equipment 1.5 mm

**Max sheet thickness (stainless steel) with pre-bending equipment 1.25 mm

- Covers the major part of your material requirements.

- Fully automated material changes in less than one minute.

- Easy control with CSV files.

- Single operator.

- Easily integrated with other production machinery.

- High speed, sharp, quality and precision.

- Reduces waste with the help of

step cut.

Pre-bending equipment for easier in feed and higher capacity.

Coil wagon for easier and safer loading of coils.

Using the run-out table, panels are automatically checked for flatness before integration and transfer to punching, bending or other processing machines.

Integrated flatness measuring unit for 100% process function.