Forstner COMPACT

Slitting

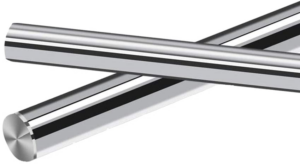

5 Sets of slitting knives come standard on the Compact series slitters. The unique “Cap-Locking” system gives you trouble free slitting the life of the machine. The shafts are 100mm. The tolerance between the shaft and blades is less that 0.01mm which gives you a smooth and easy to move positioning of the slitting blades anywhere on the shaft. The caplock consist of a half moon mild steel that presses onto the shaft by an allen head screw. Since the caplock is softer that the shaft, you do not have to worry about “scoring” the shaft like other designs tend to over time.

The knives have a two side cutting surface, so you can alternate sides and take tension out of narrow slits. The machines come standard with a red with sliver lettering on the scale for ease of reading the position of the top blade.

S1 – Control

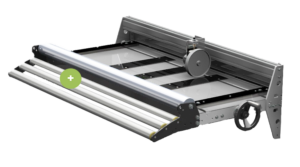

The SPS-S1 Control touch screen with intuitive features, that allow you to en-ter different quantities and lengths. The control uses the Electronic Eye to automatically set the zero point on square material. The control features a “material savings” mode which automatically stops the machine, raise the slitting knives automatically and then moves forward to cut the piece to length, while leaving a clean edge. An optional radio remote can be purchased when adding later on a powered decoiler or recoiler, so the operator has everything under control.

The Forstner COMPACT is the perfect combination. It can be used in smaller workshops as well as in larger companies with serial production. The size of the components is the decisive factor for the advantages from which you want to profit. At the heart of the machine is a robust and reliable straightening unit with six rolls and a strong slitting unit that can be equipped with the desired number of knives. The machine is well equipped as standard with a lot of features that creates a perfect working environment that meets the greatest demands on efficiency and ergonomics.

The most important advantages:

- Very robust construction.

- 6 straightening rollers with easy adjustment.

- Sophisticated and quickly adjustable slitter.

- Logical and user-friendly user interface.

| Specifications | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Machine | Type | Working width | Straightening rolls Ø | Slitting capacity – Steel 400 N/mm² |

Slitting shaft Ø | Slitting knives | Shear | ||||||||||||||||||||||||||||||||||||||||||

| mm | mm | mm | mm | pairs | |||||||||||||||||||||||||||||||||||||||||||||

| COMPACT CUT 1250 | Straight, Slit & Cut | 1250 mm | 70 mm | 1,0 mm | 100 mm | 5 | Roller shear | ||||||||||||||||||||||||||||||||||||||||||

| COMPACT CUT 1500 | Straight, Slit & Cut | 1500 mm | 70 mm | 0,8 mm | 100 mm | 5 | Roller shear | ||||||||||||||||||||||||||||||||||||||||||

| COMPACT PRO 1250 | Straight, Slit & Cut | 1250 mm | 70 mm | 1,0 mm | 100 mm | 5 | Guillotine shear | ||||||||||||||||||||||||||||||||||||||||||

| COMPACT PRO 1500 | Straight, Slit & Cut | 1500 mm | 70 mm | 0,8 mm | 100 mm | 5 | Guillotine shear | ||||||||||||||||||||||||||||||||||||||||||

The infeed guide roller are angled to match the loop of the coil from a decoiler. This helps prevent creasing on soft materials like copper, aluminum and zinc. Another helpful feature is guiding the coil into the infeed guides. Between the slitter and shear are roller guides to ensure the material guides into the shear without curling up.

The table guide has four roller bearings (two on each side) to guide the metal in the pinch rolls. The roller bearings allow the metal to move easily forward and backwards without damaging the edges. This also keeps the material straight as the material is fed into the machine helping to ensure a square cut.

The coil guide is an important component for the function and accuracy of every system. The table has a fixed and a manually adjustable coil guide with ball bearings. The adjustment of the movable coil guide is done by a hand wheel. This specific table has rollers integrated in the table to ensure a smooth surface.

5 Sets of slitting knives come standard on the Compact series slitters. The unique “Cap-Locking” system gives you trouble free slitting the life of the machine. The shafts are 100mm. The tolerance between the shaft and blades is less that 0.01mm which gives you a smooth and easy to move positioning of the slitting blades anywhere on the shaft. The caplock consist of a half moon mild steel that presses onto the shaft by an allen head screw. Since the caplock is softer that the shaft, you do not have to worry about “scoring” the shaft like other designs tend to over time.

The Compact series has 6 manual straightening rollers to remove coil set and give customers flat material every time. The rollers are made of polished steel with a 70mm diameter. The pressure of the straightening rolls is set by locking handles with reference scale.

The SPS-S1 Control touch screen with intuitive features, that allow you to en-ter different quantities and lengths. The control uses the Electronic Eye to automatically set the zero point on square material. The control features a “material savings” mode which automatically stops the machine, raise the slitting knives automatically and then moves forward to cut the piece to length, while leaving a clean edge. An optional radio remote can be purchased when adding later on a powered decoiler or recoiler, so the operator has everything under control.

The film applicator can basically be mounted on any table. Using the deflection rollers and the fully rubberized feed rollers, the protective film is pressed on almost bubble and wrinkle-free. The device type F-AG z2mo has an additional arm with tension spring for tensioning the film during the return movement. This design is only applicable for single decoiling systems.

The coil guide is an important component for the function and accuracy of every system. The table has a fixed and a manually adjustable coil guide with ball bearings. The adjustment of the movable coil guide is done by a hand wheel. This specific table has rollers integrated in the table to ensure a smooth surface.

For more demanding applications and a longer life span we recommend the hard chromed shafts on the straightener.

When you need to slit narrow strips or when doing a trim cut, we can offer you the right solution. Use our stripper rings that are perfectly suiting our slitting shafts to ensure even better slitting results.

Choose from a simple cradle up to motorized versions. Read more under respectively product.

The manual coil selector is a very cost-effective solution for quick and easy manual sheet metal changes. Up to eight coils are fixed in the manual coil selector. The desired sheet metal is manually pushed into the downstream machine via a handwheel.

Add a foot switch to your COMPACT CUT or COMPACT PRO for external start of the next order.

Do you often cut stainless steel sheets? Then your new machine should definitely be equipped with the higher-quality knives for stainless steel. The life of the blades is increased and you achieve perfect cuts over a long time. Ask your sales consultant if your application requires knives for stainless steel machining.

If you want to prepare your line for a film applicator, then the option with the fully rubberized rollers is ideal for you. This means that your line is ideally prepared for retrofitting a film applicator at any time and with ease. Fully rubberized pinch rollers available in both 1250 and 1500 mm.