nuLink CNC control system

What is the nuLink software?

Discover the power of nuLink, our state-of-the-art control system designed to revolutionize your production process. nuLink is more than just a control system – it’s your efficient and safe gateway to perfect parts, even in the hands of a beginner sheet metal machine operator.

Our user-friendly interface, accompanied by interactive graphic instructions guides the operator through each step of the process, from positioning, rotating and flipping to finishing the folded part. This intuitive approach makes even the production of complex details a breeze.

With nuLink, your production data is stored securely in a central database, ensuring easy access and streamlined operations. Plus, our web platform offers background services for quick and efficient integration and service, opening up a world of possibilities for future implementations.

nuLink isn’t just a product, it’s a promise of efficiency, simplicity, and innovation. Make the smart choice for your business – choose nuLink.

nuLink features

-

Intuitive Sheet Metal Profile Design in 3D

-

Innovative Bending Optimization and Simulation

-

Easy Management of Material and Tools

-

Streamline Processes with Connected Technology

-

Customize the Experience to Your Preferences

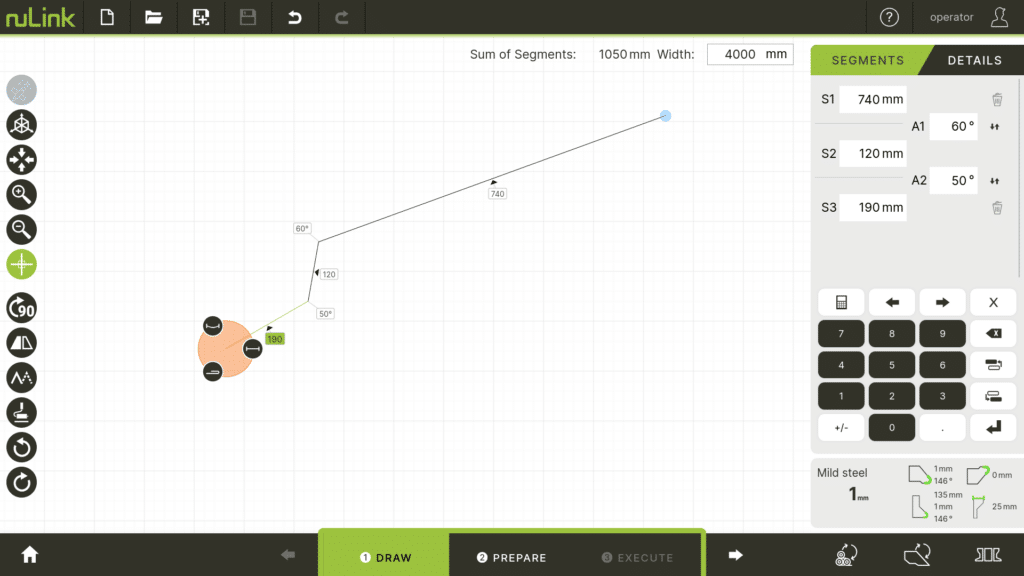

Intuitive Sheet Metal Profile Design in 3D

Discover the power of seamless production from idea to finished part is at your fingertips with this revolutionary multi-touch user interface. Select, draw and refine profiles within seconds or input your bending parameters directly in line-by-line mode to quickly start manufacturing.

It’s as easy as using a tablet!

- Quick way of creating standard boxes

- Define decorations and how they are lined up to each side

- Few clicks will generate full box

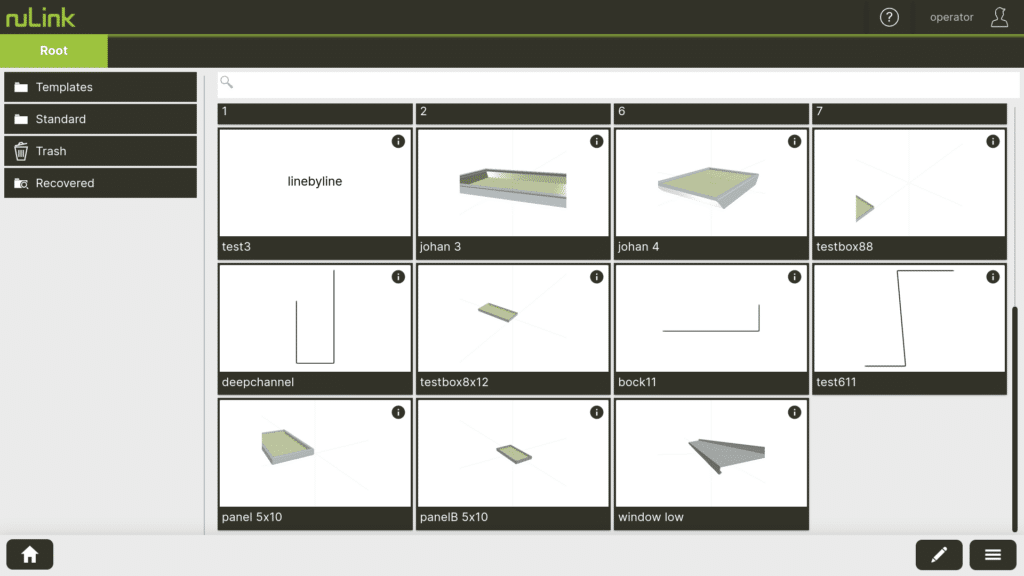

- Quickly find your stored designs by searching or scrolling previews

- Easy switch from 2D to 3D with possibility to design directly in 3D

- Draw the profiles with your fingers or set parameters Line-by-Line.

- Quickly Save, Save As and Load profiles and customize thumbnails

- Create and name folders and sub-folders to stay fully organized

- Workbench keeps drawn profile in memory after power down

- Instantly switch the colored side of painted sheet metal parts

- Rotate and zoom view freely, in increments or align with axis

- Mirror profile and repeat pattern to speed up drawing process

- Measurements and angles clearly visible in 2D and 3D

- Drag-and-Drop and Snap-to-Grid functionality

- Extra smooth radius function

- Quickly undo and redo

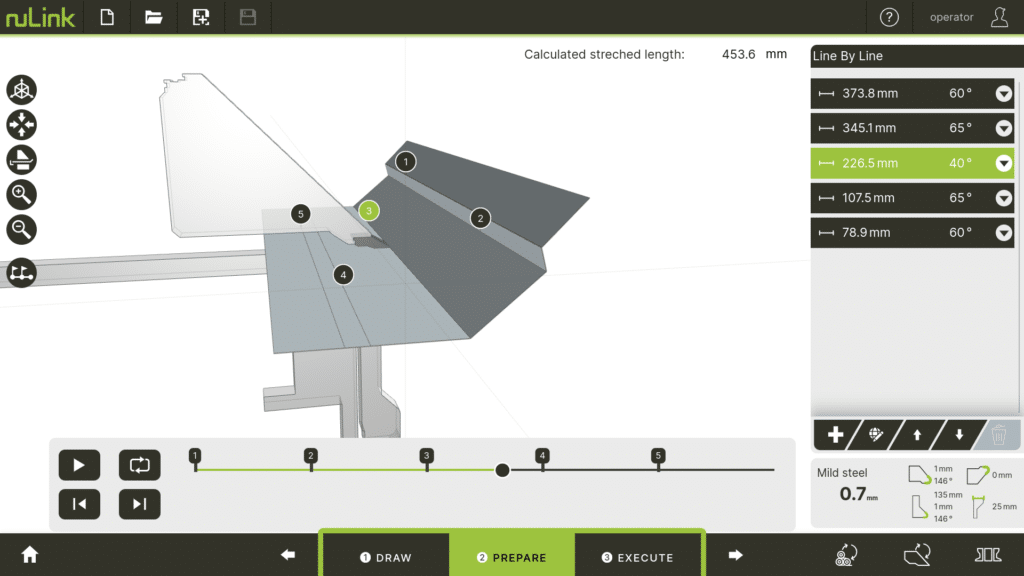

Innovative Bending Optimization and Simulation

Efficiently set up your production process via the smart preparation mode that suggests an optimal bending sequence that can easily be modified further. A guided simulation will let you visualize and inspect the machine workspace and prevents errors through collision detection.

Manufacturing has never been easier!

- Use suggested bending order or quickly modify

- Bend line parameter values easily adjustable

- Dimensions on measure points displayed

- Free camera movement in machine space

- Collision detection and change of tool setup

- Toggle between different levels of visual detail

- Play, pause and go step-by-step through bending simulation

- Easy switch between 2D to 3D part and unfolded flat pattern view

Easy Management of Material and Tools

Ensure high quality results from the very first part through automatic material compensations instead of using trial-and-error to find the right settings. When running the machine operators are given step-by-step instructions on how to run the machine and manage tools and material.

Flawless results every time!

- Easy way of setting up multiple stations for box profile

- Each station can be defined separately

- Copy function of tool stations to other tool lines

- Easy tool station selection for each bend step

- Tool station is shown highlighted for each bend step after selection

- 3D Model of machine with tool station layout

- Smart material properties via automatic material compensation selection

- Maintain and use bending tools easily and efficiently via graphical guidance

- Visualization of foot pedals to clearly and safely know how to operate machine

- Additional instructions in the selected language of the individual operator possible

- One side of sheet metal is colored to keep track of rotation and flipping the material

Streamline Processes with Connected Technology

Select from an expansive catalogue with online access to parts that are both searchable and browsable via thumbnail previews. Securely connect and integrate with other machines and use supportive services for order processing and collaboration, – from anywhere, at any time.

Your 24/7 solution for sheet metal designs!

- Online access to parts and cloud-based back-up of important data

- Platform with background services for quick support and updates

- Future product and service innovations can easily be implemented

- Connection is secured via VPN and firewall

- System is protected from virus and malware

- Connect to nuEVOLUTION to utilize all benefits of your smart factory:

- Networking of various machines from CIDAN Manufacturing Group

- Draw profiles 24/7 from anywhere

- Order tracking and storage

- Automation and process optimization

- Scheduling and production management

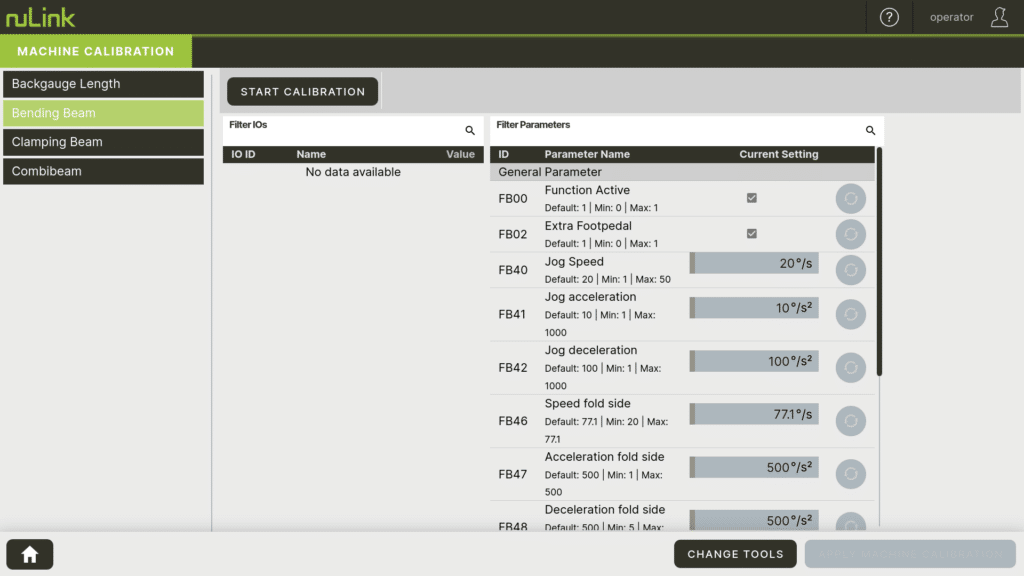

Customize the Experience to Your Preferences

From small workshops to large-scale industrial manufacturing the control system can adapt to your specific needs. Tailor it to your requirements and user preferences with our powerful administrative tools. Utilize cloud-based backups of your parts and data securely over VPN.

A personalized solution for every scale!

- Multiple language selection

- Individual operator log-in screen

- Different levels of access are available

- Powerful administrative tools for users and roles

- Configure and calibrate the setup of your machine

How to use nuLink

-

1

Find a profile in the catalogue similar to what you need by searching or browsing.

-

2

Edit the selected profile or create your own from scratch by drawing with your fingers.

-

3

Alternatively use the line-by-line programming to set the angles and dimensions directly.

-

4

Automatically calculate the folding sequence, detect collisions and fine-tune your set-up.

-

5

Follow the step-by-step folding sequence and watch how to handle the material and tools.