CIDAN FS FOLDING MACHINES

nuLink Control System

Our user-friendly interface, accompanied by interactive graphic instructions guides the operator through each step of the process, from positioning, rotating and flipping to finishing the folded part. This intuitive approach makes even the production of complex details a breeze.

Advantages of the nuLink Control System

- Intuitive Sheet Metal Profile Design in 3D

- Innovative Bending Optimization and Simulation

- Easy Management of Material and Tools

- 21? touch screen

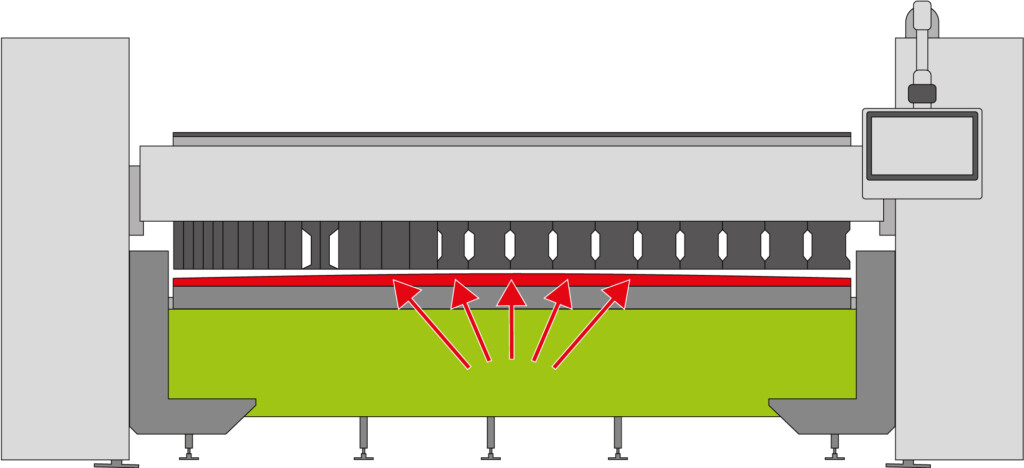

Quick change tooling and adjustable crowning

Advantages of quick change tooling and adjustable crowning

- The quick-change tooling helps operators change out tooling to correctly bend different thicknesses and types of material in a more efficient way.

- CIDAN’s FS series is equipped with adjustable crowning that allows for precise bending when forming thicker metal and radius work. This feature contributes to our goal of giving operators full control of the machine to make custom parts faster than other machines on the market.

See how easy you can adjust the crowning, click here.

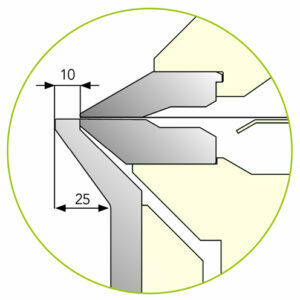

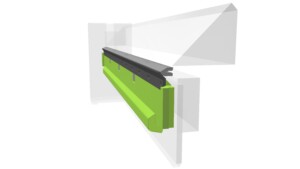

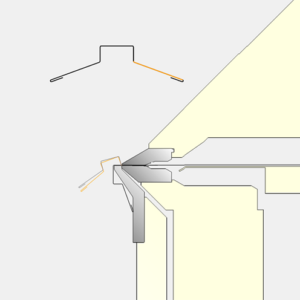

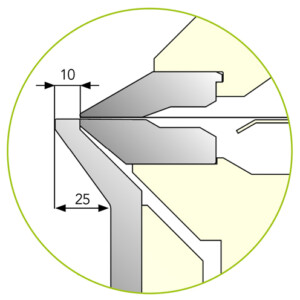

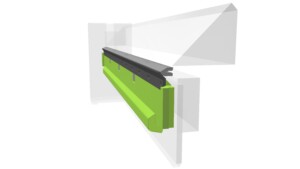

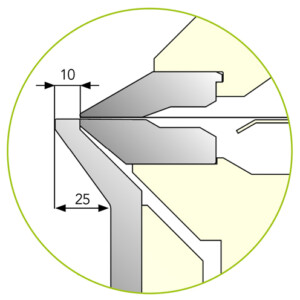

CIDAN XSPACE gives you far greater freedom to design and fold your profiles. XSPACE is the folding beam with an indented angle below the folding point giving you extra space around the tools. You can now easily make profiles that were previously difficult or impossible to fold and without risk of collisions. The 15 mm extra space below the folding beam rail allows you to fold trapezoid profiles, z-profiles and hat profiles. There is no need to “force” the material into the machine, ergonomics are improved and safety increased. The XSPACE-beam is of course equipped with crowning for zero angle deviations for long profiles. (Read more under Options.)

CIDAN FS folding machines are phenomenal combinations of raw strength and flexibility. With powerful motors that fold with fantastic precision and to exact measurements this machine can do a lot more than just bend. Together with the nuLINK control system and frequency control of the machine’s movements you have everything you need for contract manufacturing with high quality and productivity. CIDAN FS folding machines are true workhorsees with a whole lot of benefits.

- Crowning adjustment as standard always gives the perfect folding result

- Two folding beam rails with width 7/10 mm (0.275″/0.394″) and 20 mm (0.787″) as standard

- Fast, reliable, and user-friendly

- Choose between two control systems, EasyLink or nuLINK, both with plenty of features

- Multiple backgauge stops for both small and large parts across the bending length of the machine (Click here to read more about our back gauges.)

| Specifications | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Working lenght | Folding capacity | Opening height | Outer dimensions | Weight | Motor | |||||||||||||||||||||||||||||||||||||||||||

| mm (“) | Steel mm (ga) | Stainless steel mm (ga) | Aluminium mm (“) | Clamping beam mm (“) | Lenght x Width x Height mm (“) | kg (lbs) | Clamping beam kW (hp) | Folding beam kW (hp) | |||||||||||||||||||||||||||||||||||||||||

| FS26 | 2600 (102) | 2.5 (13) | 1.6 (16) | 3.7 (0.146) | 150 (5.9) | 3658 (144) x 1055 (42) x 1955 (77) | 2950 (6503) | 1.5 (2) | 1.5 (2) / 2.2 (3)* | ||||||||||||||||||||||||||||||||||||||||

| FS32 | 3200 (126) | 2 (14) | 1.2 (18) | 3 (0.125) | 150 (5.9) | 4258 (168) x 1055 (42) x 1955 (77) | 3393 (7480) | 1.5 (2) | 1.5 (2) / 2.2 (3)* | ||||||||||||||||||||||||||||||||||||||||

| FS41 | 4100 (161) | 2 (14) | 1.2 (18) | 3 (0.125) | 150 (5.9) | 5158 (203) x 1055 (42) x 1955 (77) | 4100 (9038) | 1.5 (2) | 1.5 (2) / 2.2 (3)* | ||||||||||||||||||||||||||||||||||||||||

*with ProLink W control system

- Control System EasyLink, with touch screen for input and storage of folding operations

- Clamping beam with divided straight rail 30°

- Lower beam rail

- Double sided folding beam rail 7/10 mm (.275″/.394″), with quick change tooling

- Folding beam rail 20 mm (.787″) with quick change tooling

- Adjustable crowning of folding beam rail

- Manual sheet thickness adjustment (0-50 mm)

- Foot pedal

CIDAN XSPACE gives you far greater freedom to design and fold your profiles. XSPACE is the folding beam with an indented angle below the folding point giving you extra space around the tools. You can now easily make profiles that were previously difficult or impossible to fold and without risk of collisions. The 15 mm extra space below the folding beam rail allows you to fold trapezoid profiles, z-profiles and hat profiles. There is no need to “force” the material into the machine, ergonomics are improved and safety increased. You get higher precision with no effort. All the machine’s features function as normal. The XSPACE-beam is of course equipped with crowning for zero angle deviations for long profiles. All machines in the FS-serie can be equipped with XSPACE and there are three different folding beam rails: 10, 12 and 25 mm. Enjoy greater freedom with extra space around the folding beam, XSPACE gives you all the space you need.

Discover the power of nuLINK, our state-of-the-art control system designed to revolutionize your production process. nuLINK is more than just a control system – it’s your efficient and safe gateway to perfect parts, even in the hands of a beginner sheet metal machine operator.

Our user-friendly interface, accompanied by interactive graphic instructions guides the operator through each step of the process, from positioning, rotating and flipping to finishing the folded part. This intuitive approach makes even the production of complex details a breeze.

With nuLINK, your production data is stored securely in a central database, ensuring easy access and streamlined operations. Plus, our web platform offers background services for quick and efficient integration and service, opening up a world of possibilities for future implementations.

nuLINK isn’t just a product, it’s a promise of efficiency, simplicity, and innovation. Make the smart choice for your business – choose nuLINK.

This back gauge is just as the name indicates, flexible, and expandable up to 4200 mm working depth via modules. The base unit has a depth of 1550 mm. The modules then make it possible to change a standard FLEXIBLE to an L-, J-, T- or U-shaped format from scratch or as needed. The modular system enables a variety of combinations of back gauge tables, so today a tailored back gauge is quite possible. The back gauge is equipped with dual servo motors, ball screws and linear guides for maximum precision. All positions will be exactly the same, time after time. FLEXIBLE back gauge are supplied as standard with 12, 14 or 16 gauging rails, depending on the length of the machine. The back gauge speed enables the productivity to increase and at the same time, decreases the costs of your forming operation. The front stop units are made of spring steel as standard. The stop units can be dropped down automatically in every program row, which prevents any collision with the stop units when the sheets needs to be rotated. Click here to read more about our back gauges.

The BASIC back gauge is a cost effective back gauge without the customization capabilities of the FLEXIBLE system. Designed specifically for the F, FS and FX, the BASIC 26 is equipped with 8×2 stop units, BASIC 32 with 10×2 stops units and BASIC 41 has 12×2 stop units. First row stop units are made of spring steel as standard and solid steel as an option. The back gauge has one servo motor and belt drives on both sides and it takes two seconds to get an exact position between 3 and 1050 mm (.12″–41.34″). All the stop units can drop down automatically to avoid collision when the material needs to be rotated on the table, (ball transfers are available as option).

Hardened standard tooling for 100% stainless application (HRC 45).

Makes positioning of large and narrow parts easier. Available in three lengths 1000 mm (39.3″), 1500 mm (59″) and 3000 mm (118″) for left and/or right hand side.

Straight rail and segmented box tools with 0.75 mm radius (surface hardened).

Segmented Radius Rail (R = 1.5 mm)

Safely store the divided tooling for your CIDAN folder. The tool cart is recommended to decrease the risk of damaging tools and misplacing tools during tool changing. It is possible to store divided rails on the cart and there is room for hand tools for the operators and machine instruction manual. The cart is equipped with lockable wheels and pull handles. Especially recommended if the machine is equipped with the Multifold tooling system.

The safety scanner provides extra safety with two modes when operating machine from folding side or gauging side. The scanner prohibits any person to enter the working area where a collision with the folding beam is possible.

Ball transfers on the back gauge assist with the positioning of larger, heavier parts and reduce the risk of scratching the material. (Standard on FLEXIBLE and option for EGS.)

Allows the operator to move the foot pedal quickly and smoothly along the folding area. Appropriate when folding is done with several folding stations. Especially recommended if the machine is equipped with Multifold. This option is considered a great safety feature when bolted to the floor. When operator engages foot pedal, they are away from the upcoming folding beam.

Turnable, solid front fingers in spring steel on back gauge.

Extra foot pedal available for rear operation.

We offer numerous folding beam widths of from .393″ (10mm) to .787″ (20mm).

Custom tooling is available for applications requiring large radius work, more workspace clearance, etc.

Brushes on the back gauge are ideal when positioning sheets of sensitive material such as aluminum and stainless steel. (Option for back gauge FLEXIBLE).

CIDAN FLEXIBLE is our new back gauge that is now available with angled gauge positioning for conical bending, XTAP. With a back gauge fitted with XTAP gauge, positions can be set automatically using the nuLink control system – perfect for fast and efficient production of cappings and other details without parallel sides or for profiles with easy and optimal overlap and no trimming. Just enter your values in the nuLink control system and your profiles will have perfect angles and results totally automatically! Faster, smarter and what is more, with higher quality all included!

CIDAN back gauge can also be equipped with two special fingers for conical bending. These adjustable fingers are placed at the edges of the back gauge and facilitate manual conical bending.