CIDAN Machinery Group is thrilled to introduce four smart innovations that are set to transform the sheet metal processing industry worldwide. Our Thalmann TD double folder series is now equipped with cutting-edge features that will enhance efficiency, precision, and safety like never before.

GAME CHANGER

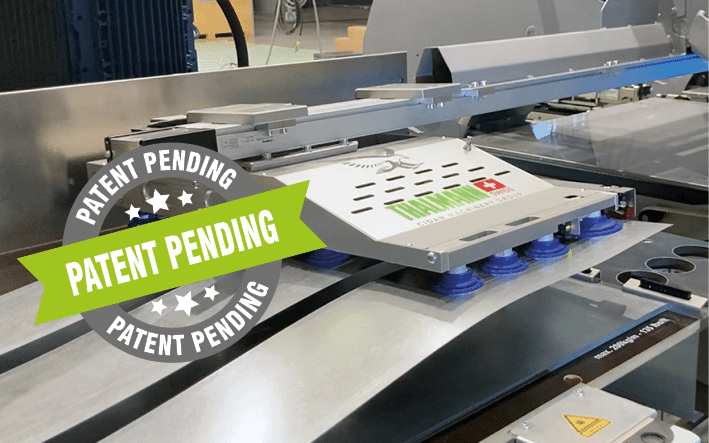

Are you ready for a revolution? Meet the Multi Head Side loader TD, a smart solution for your sheet metal processing operations. Key highlights include:

- Faster Loading: Bid farewell to time-consuming loading processes – the Multi Head Side loader TD can load up to 4 strips simultaneously in one swift motion when operating in 4 section mode. This means reduced loading times and significantly increased productivity. It’s more than 40% faster!

- Patent Pending Technology: Our smart system is underlining our pioneering spirit in the field of sheet metal processing. With THALMANN TD, you always have access to the latest advancements.

- Precision and Flexibility: Each row of the Multi Head Side loader TD is equipped with a vacuum injector and an ultrasonic sensor for precise height measurement of your stock. Our user-friendly software lets you choose whether to load one or more blanks, guiding you to optimal positioning.

- Versatile Loading: Whether you’re handling small stripes as narrow as 90 mm or larger widths, our Multi Head Side loader TD handles it all with ease, especially in section mode.

- Increased Loading Capacity: Experience less wear and tear and significantly more loading capacity compared to standard Vacuum Heads. With 16 suction cups delivering a 30% boost in suction force, you can confidently handle materials up to 2 mm thick.

CIDAN Machinery Group is committed to pushing the boundaries of innovation, and the Multi Head Side loader TD is a step in this direction.

ADDITIONAL NEW INNOVATIONS

In addition to the Multi Head Side loader TD, CIDAN Machinery Group is introducing three other smart and fast features for the Thalmann TD Double folder:

FAST LOADER – Automation and Efficiency

Say goodbye to manual interventions with our Fast Loader function. This smart solution automates back gauge positioning, eliminates the need for Gripper Offset, and allows seamless loading of small 75 mm strips in Automatic mode. Enhance gauge speed after part flipping, enabling fully Automatic Mode for profile creation.

VACUUM GRIPPER – Precision and Safety

Conquer complex scenarios with ease using the Vacuum Gripper. Achieve precise positioning in fully Automatic Mode, especially when dealing with flanges over 38 mm in height. This solution not only speeds up your processes but also enhances operator safety by eliminating manual handling.

BEST-IN-CLASS SAFETY!

Safety is paramount, and we’ve raised the bar with our Thalmann TD double folder. It now boasts best-in-class safety features, including three strategically placed scanners that cover the entire floor area (Frontside, Left, and Right sides). These scanners activate within 1250 mm (4 feet) from the bending line, ensuring the safety of operators.

An additional top-mounted scanner halts the machine when someone enters the safety area from the frontside. This intuitive and state-of-the-art safety system eliminates the need for a 2-Operator Mode in Automatic mode, enabling fast and safe panel production without factory safety pillars.

Join us in embracing the future of sheet metal processing with CIDAN Machinery Group’s enhanced Thalmann TD double folder. These smart innovations are designed to elevate your operations, enhance efficiency, and prioritize safety.