Schrag Kantprofile GmbH

Throughout Europe, customers place their trust in the SCHRAG Group, whose headquarters are located in Hilchenbach, North Rhine-Westphalia. With its four business units (flashings, facades, engineering services and metal on roofs), the Group is an association of networked specialists and offers integrated solutions for roofs and facades in lightweight metal construction. With the investment in the business field SCHRAG|Flashings in two new double folders from THALMANN, the renowned company puts its trust in the Swiss machine manufacturer. The decision was preceded by an intensive review process.

Background

After the first TD double folder was delivered to the Kirchardt-Berwangen site in Baden-Württemberg in the summer of 2018, another machine followed a good year later for the headquarters in Hilchenbach.

-Yes, we are very satisfied with our decision to go with THALMANN and would make the same decision again, said Bernd Wurmbach, Technical Manager for all 10 SCHRAG Group plants. -We took an intensive look at the folding machines of the common manufacturers in advance and put them all through their paces in equal measure.

Test criteria

Both hard (technical and business management) and soft factors (know-how, good reputation, etc.), were closely scrutinized and evaluated as part of the review and selection process.

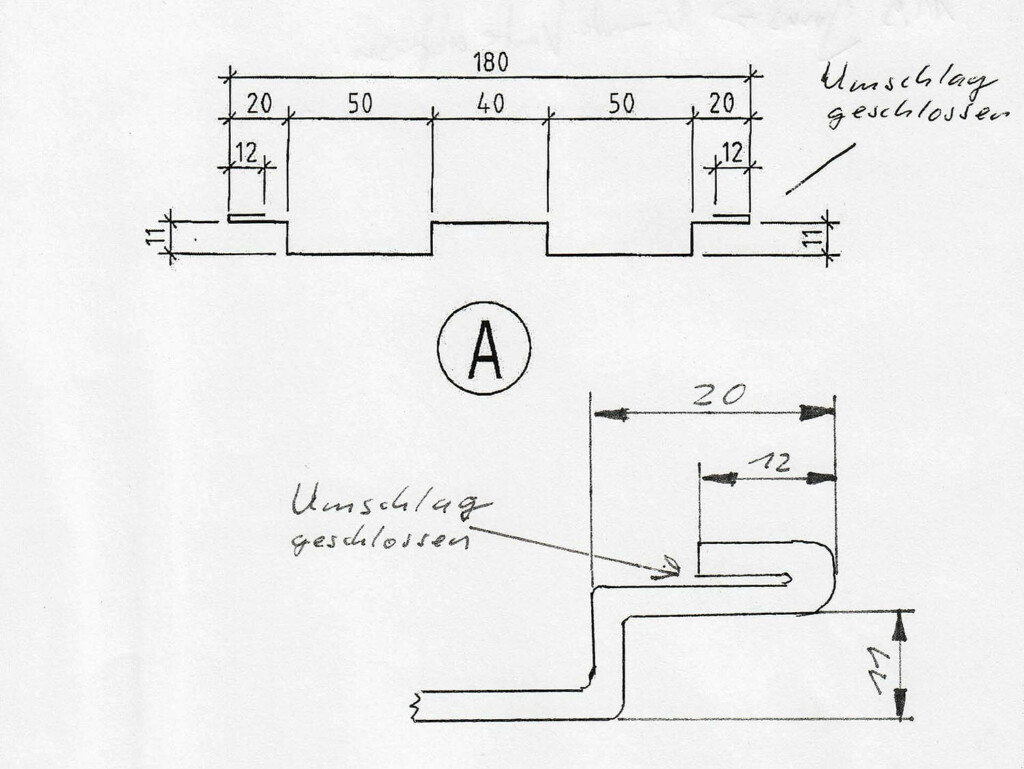

-We sent the defined manufacturers around 30 drawings with typical profile geometries of our customers in advance and then had them show us the results or demonstrate the production directly on site. We even brought two “unexpected” drawings to the demonstration date in order to check the programming speed, flexibility, operability and software compatibility of the machine in real time, reports Pascal Siepermann, plant manager in Hilchenbach.

Market demands

In addition to the standard production requirements for modern folding machines, such as high folding speed, precision, efficiency and durability, the flexibility, variability and the level of innovation are particularly important criteria for the SCHRAG company. Jürgen Stötzel, longstanding branch manager at the Kirchardt-Berwangen site, comments:

-The increasing and ever-changing market demands require maximum product diversity and reaction speed. In principle, all our edging profiles are special solutions, since, for example, hall structures come in countless sizes and variations. For this reason, we manufacture precisely fitting components from batch size 1 to n, which we also have delivered directly to the construction site for our customers as quickly as possible.

The difference

“THALMANN is a nose ahead,” states Bernd Wurmbach, who himself worked as a machine designer for SCHRAG at a partner company before he joined the company some 13 years ago. “In part, it was just little things that made the difference. For example, the TD was able to fold even increasingly small Z and U jumps in the desired profile geometries, easily, quickly and accurately. The bottom line was that the TD double folder came out on top in terms of speed, efficiency, precision, insertion depth, folding clearance, degree of innovation and flexible application options.”

The Schrag- Group

Founded in 1892 by Friedrich Schrag, SCHRAG began specializing in the manufacture and sale of edge profiles for industrial and commercial construction as early as the early 1960s. The strength of the company, and thus the basis of the customer advantage, lies in the combination of the four business areas SCHRAG|Edge Profiles, SCHRAG|Facades, SCHRAG|Engineering Services and SCHRAG|Metal on Roofs. Systematic quality controls, the highest safety standards, absolute reliability, high flexibility, short delivery times, a wide selection and prices in line with the market are the company’s credos. Under the current management of Thomas Goswin, the fourth generation to head the family business since 1994, the company currently employs over 500 people at 16 locations in Germany, Austria, Switzerland, Poland, the Czech Republic and Slovakia. The headquarters are located in Hilchenbach, North Rhine-Westphalia.

One of about 30 drawings with a typical customer profile that SCHRAG sent

to the selected manufacturers in advance and had them fold as part of the selection process.