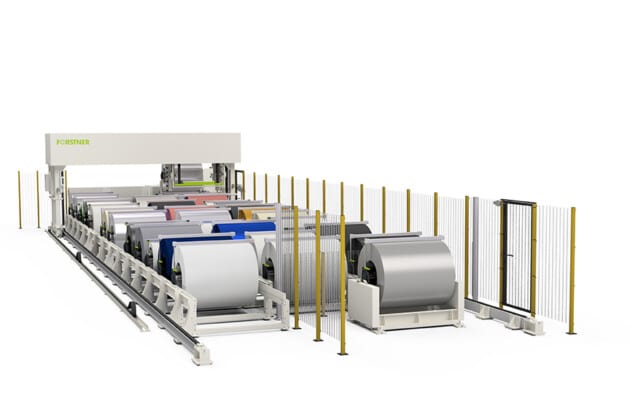

Forstner Coilfarm

The COILFARM from FORSTNER is a new, innovative, and adaptable solution to meet the changing market need for the fast, flexible availability of a wide variety of materials in a wide range of material thicknesses and color variants. This is one of the main reasons why we have developed the COILFARM for sheet metal working companies from architectural and industrial sectors.

The benefits are:

- High capacity: With a capacity of up to 75 coils, a wide range of different materials, material thicknesses and color variants can be accessed immediately and without delay. This means that even larger projects running at the same time can be managed effortlessly.

- Fast coil change: Thanks to a sophisticated system, coil change is quick, uncomplicated, and safe. This reduces set-up times to a minimum and significantly increases overall production efficiency.

- Simple loading process: The sophisticated machine design makes the loading process of the COILFARM very simple. The mandrels can be easily attached to the coil and loading via the setup station increases your productivity.

- Maximum precision: The integrated zero-line alignment (fixed edge) ensures that the materials are perfectly aligned every time. Errors and waste are thus reduced to a minimum.

- Uncompromising quality: The quality standard for products from the CIDAN Machinery Group knows no compromises. With the COILFARM development, too, our credo was to bring form and function to a common denominator.

Make your enterprise future-proof

When your company grows, the market changes and requirements increase, the FORSTNER COILFARM provides you with a reliable, flexible, and efficient machine solution. Take your production to a technically higher level and shape the world of tomorrow with us.

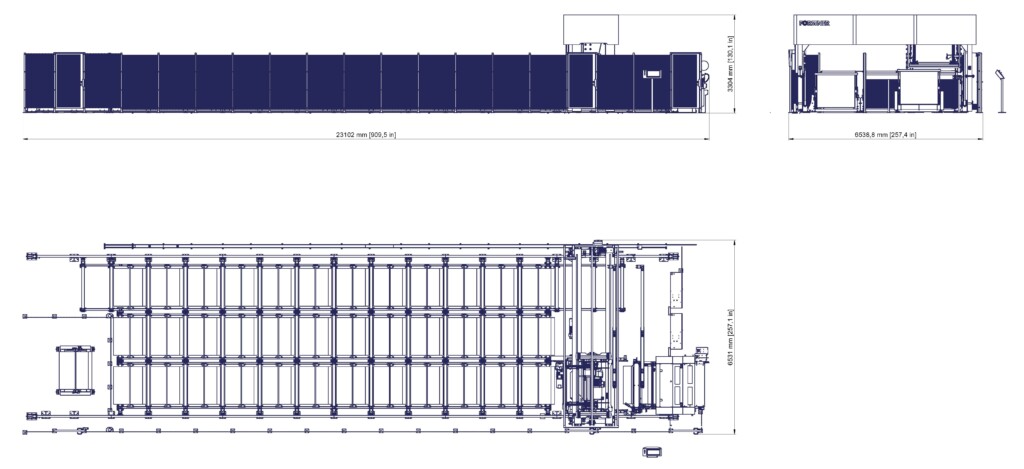

LAYOUT EXAMPLE FOR YOUR COILFARM

| Specifications | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Coil Weight | 5000 kg (11,000 lbs) | ||||||||||||||||||||||||||||||||||||||||||||||||

| Min. Coil width | 400 mm (15,75″) | ||||||||||||||||||||||||||||||||||||||||||||||||

| Max. Coil width | 1270 mm (50″) | ||||||||||||||||||||||||||||||||||||||||||||||||

| Max. Coil diameter | 1100 mm (43,3″) | ||||||||||||||||||||||||||||||||||||||||||||||||

| Coil Inner diameter |

380-550 mm (15″-21.65″) | ||||||||||||||||||||||||||||||||||||||||||||||||

| Coil Diameter Optional |

460-630 mm (18.1″-24.8″) | ||||||||||||||||||||||||||||||||||||||||||||||||

| Slitting Capacity – on nuSLIT | 1.0 mm (20ga) Mild steel with 5 knife pairs | ||||||||||||||||||||||||||||||||||||||||||||||||

| Shearing Capacity – on nuSLIT |

1.0 mm (20ga) Mild steel | ||||||||||||||||||||||||||||||||||||||||||||||||

| Material – Steel 58KSI (400MPa) | 1.0 mm (20ga) Mild steel with 5 knife pairs | ||||||||||||||||||||||||||||||||||||||||||||||||

| Material – Stainless 87KSI (600MPa) | 0.8 mm (22ga) Stainless steel with 5 knife pairs | ||||||||||||||||||||||||||||||||||||||||||||||||

| Material – Aluminum 43KSI (300MPa) |

1.2 mm (0.50″) Aluminum with 5 knife pairs | ||||||||||||||||||||||||||||||||||||||||||||||||

| Coil Storage Maximum – optional |

72 Coils at maximum diameter | ||||||||||||||||||||||||||||||||||||||||||||||||

| Sheet infeed | 1150 mm (45.27″) | ||||||||||||||||||||||||||||||||||||||||||||||||

| Power |

400V 60amp | ||||||||||||||||||||||||||||||||||||||||||||||||

Step into intelligent coil management with the 19-inch Industrial Touch Panel HMI. This independent coil store interface allows the operator to optimize and reload the coil store without interrupting machine production – a blend of intuitive design and efficiency that ensures seamless operation. The control – with integrated nuIT software displays all coils with location, material type, thickness, color of the coil and the number of meters remaining on the coil.

To feed the coils quickly, safely and with pinpoint accuracy, a zero-line alignment (fixed edge) is integrated into the system. Housed in a separate safety zone, it ensures set-up without interfering with the running machine processes.

The gantry crane, built on a double-rail foundation, is characterized by its robust design, high speed, and pinpoint positioning accuracy. It was developed based on modern crane technology and ensures durable, safe, and reliable operation for many years.

The double lifting device picks up the coil and transports it safely, quickly, and efficiently. Roller-bearing guides ensure safe lifting of the coil on the gantry crane.

The ultrasonic coil sensor is designed to not only measure the diameter of the coil to determine placement on the storage rail, but it also measures the estimated length of the coil. Precision and efficiency – combined in one sensor.

Coil storage is available in 3 widths and up to 72 coils at full diameter (50″ or 1270 mm). If the coils are smaller, more coils can be stored on the rails.

Coil buffer station for quick change of coils into the nuSLIT (slitting and cutting to length), one coil is placed above the nuSLIT for quick efficient set-up.

A laser arm – which measures the position of the coil edge – ensures that the lifting device is either raised or lowered and thus the feed to the coil edge is correct. This is because overnight, or even when the coil is curing during the day, the coil edges lower.

If the coil is not on the zero line for the infeed, the infeed table shifts to pick up the coil in the nuSLIT coil unit.

Segmented infeed pinch rollers safely and precisely guide the material into the nuSLIT coil unit.

The system places the coil in the decoiler station after the edge of the coil has been inserted into nuSLIT. The decoiler combines a powerful motor-driven mechanism with precise design. Tailored for high-speed production, it promises consistent and reliable unwinding and increases efficiency and output quality in every cycle.

Behind the decoiler, the system stacks the coil in use and places it in the programmed permanent staging position when the next coil unwinds and cuts sheets. This ensures that there is no downtime.

Maximize your production potential by combining the COILFARM with our slitting and cut-to-length lines (CTL). These machines are not only robust, but also compact all-in-ones that have been carefully designed for durable, highly efficient production while optimizing your workspace. Together, the COILFARM and the slitting and cut-to-length lines form a synergy, offering both efficiency and durability in a compact footprint.