Combi Beam

The combi beam tool changer was invented in 1987 by CIDAN Machinery and is one of our most important developments. The combi beam is an automatic tool changer that holds two different tooling systems – a straight 30 degree rail and a segmented box tooling with a height from 100mm up to 254mm or 4-10 inches.

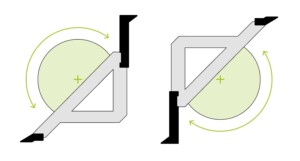

This unique tooling solution rotates and will change your tooling setup in less than 10 seconds. There are absolutely no adjustments or settings to be made when changing from one tool to another. Even the opening height remains the same when changing from the straight rail to a box tooling making it so the operator can easily remove the part from the machine after the bending process is complete.

This tool changer saves enormous amounts of time on tool changing and the operator can finish the complete panel or box in one sequence only. Other bending systems require a manual tool change where the part will have to be put on hold during the changing of the tooling.

Having invested in our combi beam tool system, you will probably not spend any more money on tooling for the next 5-10 years. With this tooling, any profile or shape imaginable can be made including hemming and radius bending.

Click here to see the advantages and possibilties with rotating Combi beam.