QZ36 PANEL ROLLFORMER

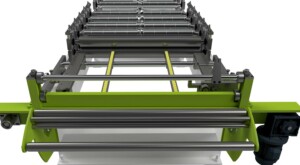

The front roller shear allows customers to not waste material when forming the final panels of a job. The AMK Control will calculate when the rollformer needs to stop and cut the coil from the job. After the coil is cut, the rollformer will feed the final pieces forward to the post shear in the rear of the machine for final cut. The roller shear comes standard with a hold down beam for accurate straight cuts.

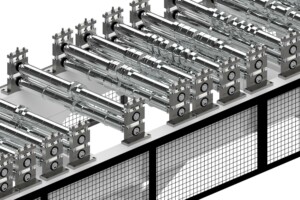

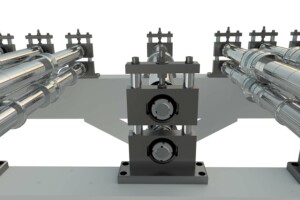

14-30 tool stations help form the desired panel. Each tool station has a dial indicator for tool height making it easy to change material thickness. The 85 mm shafts are solid and keyed. Roller dies are made of Cr45 with hard chrome surface. All tooling is designed with Cobra Engineering design software. The side housings use a sealed swivel bearing for smooth transmission of the drive.

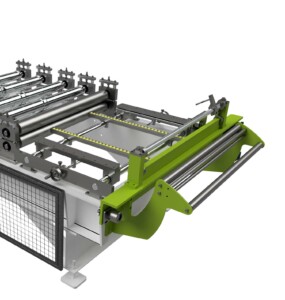

The Electric Post Shear is guided by 4 bearing shafts for burr free cutting of the panel. The post shear enables you to cut from small 100 mm long panels, up to 18.3 m. The electric motor allows for maintenance-free running at high-efficiency energy savings. The post shear has a spring-loaded hold down, to stabilize the panel during the cutting process.

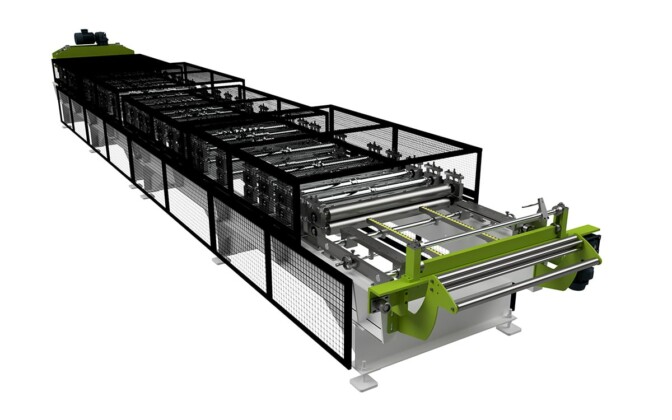

The CIDAN QZ36 panel rollformer is one of the most robust and expertly constructed in the industry. If you are looking for long-lasting, this machine’s 22 stations with a 3.375″ (85 mm) solid-keyed shaft make it built to endure. With the AMK Control, you can program up to 50 lines with different qualities and length. This control features a “material savings” mode that automatically stops the machine and repositions so you can get the most out of your material. Avoid high maintenance costs and wasted material with the CIDAN QZ36 corrugated, PBR, or AG Panel rollformer!

- Infeed has hardened roller bearing guides that ensures the material guides perfectly into the roll stations.

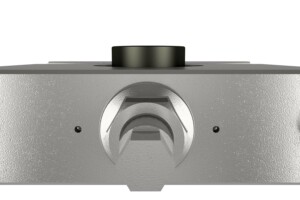

- Front Rotary Cut allows the customer to cut back on wasted material.

- 22 Tool Stations help form the Profile Panel.

- The encoder features a wheel that sits on top of the panel passing through the machine. The tension spring allows constant contact of the encoder with the coil for consistent and accurate lengths.

- The hydraulic Post Shear is guided by 4 bearing shafts for burr free cutting of the panel. The post shear enables cuts of 4” (100mm) long panels to 60’ (18.3m).

| SPECIFICATIONS | |||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | AMK Control | Hydraulic Post Shear | Stations | Solid Keyed Shafts | |||||||||||||||||||||||||||||||||||||||||||

| Lines | Bearing Shafts | Capacity Range | Quantity | ” (mm) | |||||||||||||||||||||||||||||||||||||||||||

| QZ36 | 50 Lines | 4 Bearing Shafts | 4″ (100mm) – 720″ (18288m) | 22 | 3.375″ (85mm) | ||||||||||||||||||||||||||||||||||||||||||

- 20 station, 3.375″ (85mm) solid-keyed shafts

- AMK Control, program up to 50 lines

- “Material Savings” mode – automatically stops the machine and repositions material

- Corrugated, PBR, AG Panel

- Infeed has hardened roller bearing guides

- Front Rotary Cut allows the customer to cut back on wasted material

We offer also a CNC Cut-to-length on top of rollformer with run out supports.

Rollout safety cages in lieu of quick change side cages.

Stack the finished parts on an stacker. Available in different lenghts with a capacity of up to 3500 kg.