Products CIDAN MEGAPRO FOLDING MACHINE

CIDAN MEGAPRO FOLDING MACHINE

Automatic Tool Locking

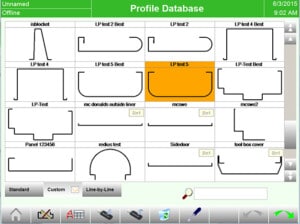

Tool changes can now be made even faster thanks to the auto-locking, the built-in tool storage as well as the new tool layout in the updated control system, ProLink W. A newly developed construction of the folding beam, automatic folding center and sheet thickness adjustment provides superior folding quality in all thicknesses without requiring crowning.

Height Adjustable Back Gauge

The back gauge table is often the single most important item when investing in a power folder. It can save businesses time and money if the system is flexible and fully incorporated with a control system.

Our strong SBG back gauge table is available with motorized adjustable height. With the height adjustable back gauge, the standard unit spans over the length of the machine and has a depth of 1550 mm (61″). SBG back gauges is also available as J- or U-shaped with a total depth of 4100 mm.

The CNC control ProLink W guarantees that the back gauge table automatically adjusts and moves when you reach the next step in the sequence. Height adjustable back gauge requires multifold execution.

CIDAN MEGAPRO folding machine is an extremely strong and sturdy folding machine. With its dual servo driven motors for both clamping and folding beams, it produces 60 tons (66 US) of clamping pressure. This sheet metal folder is not just strong, it is incredibly intelligent, providing advanced CNC folder functions as standard features. The automatic adjustment for sheet thickness, folding center, and crowning along with the automatic tool locking-system makes the CIDAN MEGAPRO folding machine the perfect brawn and brains machine for your shop.

- Dual servo driven motors for both clamping and folding beams gives incredibly fast speed and accuracy. High clamping pressure of 60 tons (66US) for accurate forming.

- CNC adjustment of folding center, sheet thickness and crowning in ProLink W control system.

- The clamping beam opens as the folding beam returns so that they are positioned for the next step simultaneously.

| SPECIFICATIONS | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Folding Length | Folding Capacity | Machine Dimensions | Weight | |||||||||||||||||||||||||||||||||||||||||||||

| ” (mm) | Mild Steel | Stainless Steel | Aluminum | Length | Width | Height | lbs (kg) | ||||||||||||||||||||||||||||||||||||||||||

| MEGAPRO 30 | 122″ (3100mm) |

0.236″ (6.00mm) |

0.149″ (3.80mm) |

0.354″ (9.00mm) |

185″ (4700mm) |

97″ (2488mm) |

89″ (2250mm) |

26,124 lbs (11850kg) |

|||||||||||||||||||||||||||||||||||||||||

| MEGAPRO 40 | 161″ (4100mm) |

0.197″ (5.00mm) |

0.126″ (3.20mm) |

0.295″ (7.50mm) |

224″ (5700mm) |

97″ (2488mm) |

89″ (2250mm) |

30,159 lbs (13680kg) |

|||||||||||||||||||||||||||||||||||||||||

- Control System ProLink control with 18.5″ touch screen and graphic programming

- Automatic crowning of folding beam rail

- Frequency/servo driven motors for both clamping and folding beams

- Automatic adjustment of sheet thickness 0-80 mm (0-3.15″)

- Motorized adjustment of folding center 0-80 mm (0-3.15″)

- Automatic lubrication

- Foot pedal

Motorized back gauge SBG with twice the amount of ball transfers as standard. SBG back gauge is equipped with ball screw, linear guides and servo motor for highest precision and repeatability. The back gauge speed enables the productivity to increase and at the same time, decreases the costs of your forming operation. Front stop units are made of spring steel as standard, solid front stop units are optional. The stop units can be dropped down automatically in every program row, which prevents any collision with the stop units when the sheet needs to be rotated. Back gauge panels can be moved backwards when folded details requires free space behind the lower beam tool. Click here to read more about our back gauges.

Solid back gauge fingers (min. dimension 9 mm/.315?)

Makes positioning of large and narrow parts easier. Available in three lengths 1000 mm (39.3″), 1500 mm (59″) and 3000 mm (118″) for left and/or right hand side.

Our robust back gauge system SBG can be supplied with height adjustment as an option. This is perfect for gauging reverse z-flanges on the back gauge. Height adjustable back gauge requires multifold execution. Height adjustable back gauge adjustment ranges from 0-5mm/ 2.6″.

High divieded tooling 102 or 152 mm height with automatic locking system.

Straight rail 35°, radius 1.5 mm, divided in 5 segments.

Divided lower beam rail (height 51 mm / 2.05”).

We offer numerous divided folding beam widths from 20 mm, 40 mm and 60 mm.

Hardened standard tooling for 100% stainless application (undivided HRC 45, divided HRC 55).

Add the optional safety bumper for a safer working environment.

Allows the operator to move the foot pedal quickly and smoothly along the folding area. Appropriate when folding is done with several folding stations. Especially recommended if the machine is equipped with Multifold. This option is considered a great safety feature when bolted to the floor. When operator engages foot pedal, they are away from the upcoming folding beam.

The safety scanner provides extra safety with two modes when operating machine from folding side or gauging side. The scanner prohibits any person to enter the working area where a collision with the folding beam is possible.

Safely store the divided tooling for your CIDAN folder. The tool cart is recommended to decrease the risk of damaging tools and misplacing tools during tool changing. It is possible to store divided rails on the cart and there is room for hand tools for the operators and machine instruction manual. The cart is equipped with lockable wheels and pull handles. Especially recommended if the machine is equipped with the Multifold tooling system.

21.5 “widescreen instead of 18.5” to ProLink W.

With the offline-software option on ProLink W, programming can be completed in the office away from the machine.

6 outputs for ProLink W.

Prepared for robot. With robot you get a fully automatic production unit.

Extra foot pedal available for rear operation.