CIDAN RAPIDO metal shear

CIDAN RAPIDO metal shear is an electrical guillotine shear that works fully independent of oil or hydraulics and emphasizes our philosophy regarding the environment with very little energy and low noise output. The drive system with eccentrics, pulldown rods, and hold down system which can be positioned as close as 30 mm from the knives allow for easy and expedient trimming of narrow strips. The CIDAN RAPIDO metal shear is equipped with the CutLink control system, capable of saving several programs, automatically shifting the machine from one step to the next. This already well-equipped machine also has a wide range of options including different back gauge and sheet handling systems.

- Shear can cut all material qualities – mild steel from 0,4 mm (28 gauge) up to 2,5 mm (13 gauge) without any settings at all and the blade gap stays the same.

- Fully mechanical, electrical, no use of oil – not hydraulic.

- Drive system with eccentrics and pulldown rod connected to the upper blade beam.

- Material is clamped between the table and the hold down beam. The beam has a rubber strip to protect sensitive material from getting marks.

- Standard squaring arm and table extension (option).

- Different modes of cutting – single cuts, continuous cuts.

- Sheet handling system called return to sender will deliver the cutoff sheet to the front for easy accessibility.

| SPECIFICATIONS | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Working Length | Material Thickness | Speed | Weight | |||||||||||||||||||||||||||||||||||||||||||||

| ” (mm) | Steel | Stainless Steel | Aluminium | Cuts/min | lbs (kg) | ||||||||||||||||||||||||||||||||||||||||||||

| RAPIDO 13 | 53” (1350mm) | 10 ga (3.50mm) | 14 ga (2.00mm) | 0.196 “(5.00mm) | 35 cuts/min | 3,100 lbs (1400kg) | |||||||||||||||||||||||||||||||||||||||||||

| RAPIDO 26 | 100” (2600mm) | 13 ga (2.50mm) | 16 ga (1.50mm) | 0.157 ” (4.00mm) | 35 cuts/min | 4,300 lbs (1950kg) | |||||||||||||||||||||||||||||||||||||||||||

| RAPIDO 32 | 126” (3200mm) | 13 ga (2.50mm) | 16 ga (1.50mm) | 0.157 ” (4.00mm) | 35 cuts/min | 4,630 lbs (2100kg) | |||||||||||||||||||||||||||||||||||||||||||

| RAPIDO 41 | 161” (4100mm) | 16 ga (1.50mm) | 24 ga (0.60mm) | 0.08 ” (2.20mm) | 35 cuts/min | 5,511 lbs (2500kg) | |||||||||||||||||||||||||||||||||||||||||||

- 750 mm motorized back gauge with CutLink control system

- Single or continuous stroke control

- Double edged blades

- LED cutting line light

- Finger protection

- Squaring arms on both sides, 380 mm with scale

- Table with scored measuring lines

- Spring loaded hold down beam

- Button to start the cut at the electrical cabinet

- Foot pedal to start cut

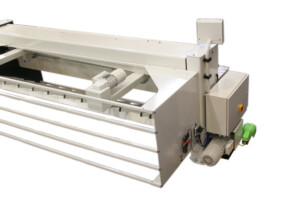

- Pneumatic sheet support including return plate (blanks to front side of shear)

Motorized back gauge with CutLink control system and ball screws 1000 mm.

The moveable material wagon is offered as an alternative to fixed return plate for return to sender option. Easily move cut material to another workstation with this option. Plus, it can be picked up with a forklift. Features include: lockable wheels and removable handle.

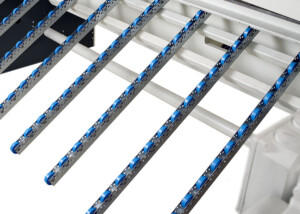

The sheet support is pneumatically controlled for maximum control. This option means that cut off material delivers on rails with rolls to the rear of the machine. The back gauge is 1000 mm and also equipped with a fixed return plate, where narrow cut off material will be delivered to the front of the machine depending on material, type, width and thickness (return to sender).

Not an option for RAPIDO 13 and 41.

Extra rails with rolls for pneumatic sheet support with delivery to rear, max 14 rails for RAPIDO 26 and 16 rails for RAPIDO 32.

Suitable when cutting a lot of soft and sensitive material.

Fixed protective device on the back of the machine, rear fixed or with lightguard

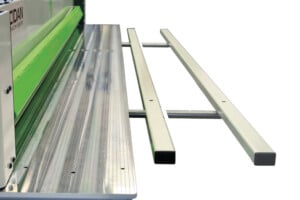

Squaringarm with or without T-groove and tilt stop. Available in lengths of 1000 mm and 2500 mm for RAPIDO.

Extendable table extension for RAPIDO, 800 mm (option).

Forced cooling of the cuttingmotor for continuous high volume cutting