CUTTING EDGE MECHANICAL SOLUTIONS

FORSTNER from Feldkirch in Austria has been developing and producing modular coil lines for sheet metal cutting since 1960. The internationally active machine manufacturer is today one of the world market leaders and offers its customers from craft and industry standard-setting straightening, slitting and cut-to-length lines for economical sheet metal processing.

HERBERT’S HERITAGE

Company founder Herbert Forstner probably had no idea that he laid the foundation for a globally flourishing mechanical engineering company 62 years ago, that today employs around 65 people and has been an integral part of the CIDAN Machinery Group since 2018. In addition to CIDAN Machinery from Sweden, the globally active group also includes the Austrian-based software company nuIT and the renowned Swiss manufacturer of long folding machines THALMANN, with a total of around 300 employees.

ALL IN ONE PLACE

The unique customer advantage of this group of companies is that the CIDAN Group offers its customers a wide range of machines, tried-and-tested software solutions and diverse service packages – all in the sense of a one-stop partner as everything is from one source and with one contact person. CIDAN supports its customers in their business development and offers future-oriented solutions for every company size and every need. This ranges from individual and used machines for start-ups and small roofers’ businesses to finely tuned machine parks for medium-sized companies and fully automated, highly efficient large-scale production plants for industrial companies.

“We accompany our customers in their growth and offer them customized machine solutions in combination with easy-to-use software applications and individual services.”

Raphael Büchel, Sales Manager of CIDAN Machinery Group

THE PERFECT CUT

For FORSTNER, impeccable sheet metal cuts are the top priority with easy material handling, gentle sheet guiding, integrated straightening, fast cutting to length and maximum cutting precision. It makes no difference whether the sheet metal is fed to the machines directly from the coil or in the form of metal sheets – one large piece or many different – waste-optimized individual sheet metal strips are to be cut.

Their machines ensure that all sheet blanks are perfectly prepared for the downstream bending process with other machines. Alternating pairs of slitting knives – an exclusive FORSTNER design – ensure twist-free sheet blanks, an innovative knife clamping system guarantees maximum production reliability and, most recently, cut-off optimization can be integrated for many machine models. The modular design also allows a high degree of flexibility and possibilities for an individual, demand-optimized machine configuration that fits the budget.

SHAPING TOMORROW’S WORLD

The CIDAN Machinery Group’s brand message is “Shaping tomorrow´s world”. The trade fair team looks forward to welcoming customers and interested visitors in person at the BLE.CH in Bern in Hall 2.0, Stand B10.

www.cidanmachinery.com

Sales Manager Raphael Büchel and his team accompany customers as they grow

and aim to be a fair, competent business partner at eye level.

The stately FORSTNER company building is in Feldkirch,

the second largest city in the Austrian province of Voralberg – a few kilometers from Lake Constance.

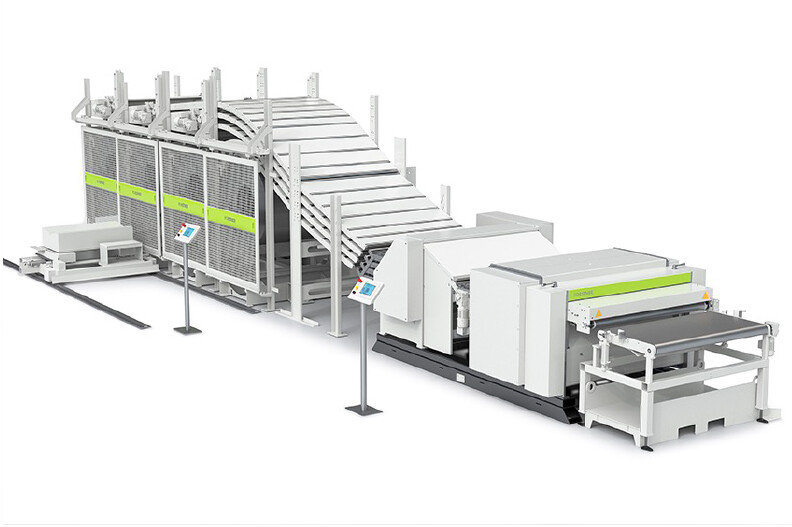

FORSTNER develops and produces high-quality coil lines

for craft and industrial companies on a production and assembly area of around 5000 m2.

Around 65 highly trained and cheerful employees work with

passion and craftsmanship on the quality machines from Austria.

The coil systems from FORSTNER impress with numerous innovations

such as alternating pairs of slitting knives for torsion-free sheet metal cuts.

Many well-known industrial companies from all over the world rely on FORSTNER’s large,

highly efficient and partly fully automated multiple decoiling lines.