FORMA Z folding machine

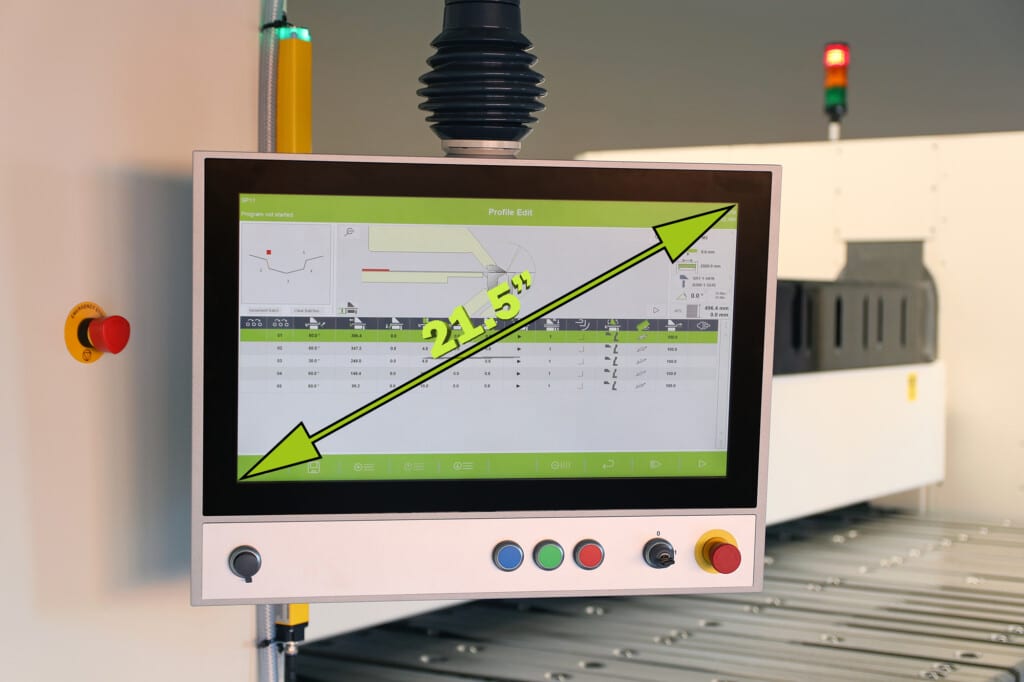

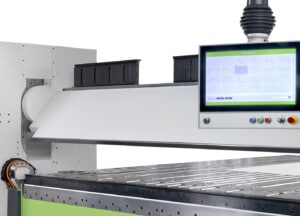

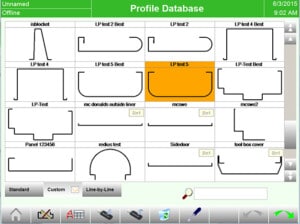

ProLink Control System

Our ProLink software offers easy and local programming, helping you add more functionality to your metal forming production. Take your programming to the next level with the convenience and efficiency of automation.

Advantages of the ProLink Control System

- Large 21.5” display

- Automatic folding and collision detection

- Machine to profile interfacing

- Remote offline programming

- Adjustable and flexible touch screen

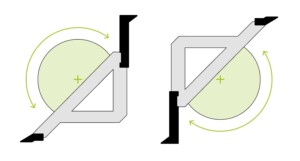

Combi Beam Tool Changer

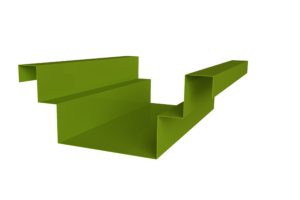

The Combi beam offers flexibility like no other tooling system. With a simple rotation of the upper beam, you can switch between the straight rail and box tooling in a matter of seconds. This gives the ability to form a larger variety of parts with little or no tool changing.

Advantages of the Combi beam

- Quick tool changes

- Large space around the tools

- Increased flexibility

- Same opening height regardless of tool selection

- 203mm (8″) high divided tooling standard

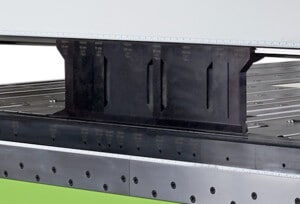

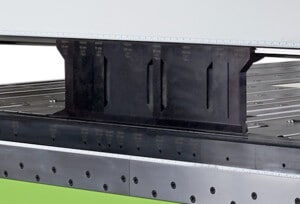

Height Adjustable Back Gauge

The back gauge table is often the single most important item when investing in a power folder. It can save businesses time and money if the system is flexible and fully incorporated with a control system.

Our versatile AGS back gauge table is available with motorized adjustable height. With the height adjustable back gauge, a U-Shaped base unit comes standard which spans over the length of the machine and has a depth of 1550/1050/1550 mm (61/41.3/61″). Add different modules to the right, left or in the middle, up to a total depth of 4300 mm (169″).

The CNC control ProLink guarantees that the back gauge table automatically adjusts and moves when you reach the next step in the sequence. Height adjustable back gauge requires multifold execution.

Vacuum Cup System

The optional feature of adding a suction cup system to the AGS backgauge takes your machine one step closer to automation. The suction cup system can work with a variety of materials to automate the load, bend sequence advancement, and also unloading of material. This in conjunction of the ergonomic advantages of up/down forming will correlate into safer and more efficient part output.

Advantages of the Vacuum Cup System

- Safer operation

- Faster automation

- Flexibility with robotic automation

Up/down bending & forming

With the Up-Down folding feature, this machine eliminates the need for an operator to flip materials with low energy consumption and noise level. Short cycle times, precision flange dimensions and angles, high levels of productivity and low costs per part guarantee a quick payback of the investment.

Our up/down folders with optional features make them the most flexible and unique machines in the market. Equip the FORMA Z with vacuum tables to help create more automation in your forming department.

Advantages of up/down bending & forming

- No part flipping required

- Fast folding sequences of complex details with one operator

- Maximum flexibility with automatic tool locking

NOW EVEN QUICKER!

FORMA Z folding machine is the most flexible and diverse sheet metal folding machine in our portfolio. Folding both up and down, FORMA Z folding machine eliminates the need to flip material, providing time-efficient folding of complex parts using one operator. The Combi beam rotation between two tooling set ups and the unique geometry gives you unrivalled working space. The automatic tool locking is fast and has features making tool changing very ergonomical. The folding beam has automatic crowning, automatic folding center adjustment and automatic sheet thickness adjustment, which provides superior folding quality in all thicknesses and across the folding length. The large number of vacuum grippers holds the part steadily, anywhere on the back gauge. Large blanks as well as small, one as well as several. The back gauge comes in many designs, which gives you great freedom of choice in how you would like to operate the machine and manage the flow of blanks and parts to/from the machine. Last, but not least – FORMA Z is fast: more production in less time for you!

- CNC controlled crowning of folding beam

- CNC folder that folds upward and downward, no need to flip the material.

- 150 mm movement of folding beam, to move outside of material on folding side.

- The Combi beam comes equipped with 203 mm (8”) High Divided Tools and straight rail.

- Comes as standard with multifold tooling, CNC controlled sheet thickness and folding center adjustment.

- The folding beam can be used as front gauge up to 150 mm.

- Add vacuum grippers to make work lighter, more precise, and automated!

| Specifications | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Folding Length | Folding Capacity | Opening Height | Outer Dimensions**** | Weight | Motor | |||||||||||||||||||||||||||||||||||||||||||

| mm (“) |

Steel* mm (ga) |

Stainless steel** mm (ga) |

Aluminum*** mm (“) |

Clamping beam mm (“) |

Length x depth x height mm (“) |

kg (lbs) | Clamping beam kW (hp) |

Folding beam kW(hp) |

|||||||||||||||||||||||||||||||||||||||||

| FORMA Z 32 | 3200 (126) |

3.0 (11) |

2.0 (14) |

4.5 (0.177) |

210 (8.3) |

4900 (193) x 2750 (108) x 2000 (78) | 6960 (15344) | 2 x 1.1 (2 x 1.5) |

2 x 4.0 (2 x 5.4) |

||||||||||||||||||||||||||||||||||||||||

| FORMA Z 41 | 4100 (161) |

2.0 (14) |

1.4 (17) |

3.5 (0.138) |

210 (8.3) |

5800 (228) x 2750 (108) x 2000 (78) | 8350 (18408) |

2 x 1.1 (2 x 1.5) |

2 x 4.0 (2 x 5.4) |

||||||||||||||||||||||||||||||||||||||||

Tensile strength *at 400 N/mm2–58000 lbf/in2 (psi) – **at 600 N/mm2–87000 lbf/in2 (psi) – ***at 200 N/mm2–29000 lbf/in2 (psi) – ****With motorized back gauge AGS

- CNC controlled crowning of folding beam

- CNC folder that folds upward and downward, no need to flip the material

- Control System ProLink W 21.5″ widescreen with integrated buttons

- CNC controlled sheet thickness and folding center

- Multifold: all three beams have segmented tools

- The folding beam is delivered with either 8 mm ( .3″), 12 mm (.47″), 15 mm (.6″) or 25 mm (.98″) segmented tools

- Floor scanner on folding beam side, light curtain on both folding and gauging side

- Back gauge can be delivered with vacuum gripper; and/or with height adjustment – all to your wish; minimum gauging is 6 mm for spring steel fingers (AGS)

- Automatic lock of high divided and folding beam tools

- Automatic lubrication

- Integrated tool storage on left hand side (viewed from folding side).

Motorized back gauge AGS with ball transfers. With our customers seeking more customized and flexible back gauges our latest system is our most innovative and flexible so far. With the AGS back gauge you can design your back gauge exactly to your needs. The base unit spans over the length of the machine and has a depth of 1550/1050/1550 mm (61/41.3/61″). Then you can install additional modules to the right or left up to a total depth of 4300 mm (169″) and add in the middle section as well. You choose if you want your back gauge straight or shaped as a J, L or U. Should your needs change, you can with reasonable effort expand your back gauge by adding modules afterwards. AGS back gauge is equipped with ball screw, linear guides and servo motor for highest precision and repeatability. The back gauge speed enables the productivity to increase and at the same time, decreases the costs of your forming operation. Front stop units are made of spring steel as standard, solid front stop units are optional. The stop units can be dropped down automatically in every program row, which prevents any collision with the stop units when the sheet needs to be rotated. Click here to read more about our back gauges.

For large applications like panels, doors and cabinets, we recommend a J-shaped or U-shaped back gauge. With the expandable back gauge table, the operator can choose to work either at the folding or gauging side of the machine. Even 3 and 4 m parts can easily be handled by one operator. A standard AGS back gauge table can be expanded to a J-, L-or U-shaped back gauge table afterwards. Click here to read more about our back gauges.

Our robust back gauge system AGS can be supplied with height adjustment as an option. This is perfect for gauging reverse z-flanges on the back gauge.

Available options for straight rail are:

Straight rail 30°, S1 shape on nose

Straight rail 30°, Radius 1mm on nose

Straight rail 28°, Radius 2mm on nose

Other nose radiuses can be supplied upon request. Choose from three options regarding tool quality: Standard, hardened or premium.

Available options for the 203 mm high divided tools are:

S1 shape on nose

Radius 1mm on nose

Radius 2mm on nose

Other nose radiuses can be supplied upon request. Choose from three options regarding tool quality: Standard, hardened or premium.

Divided folding beam rails, 8 mm 12 mm, 15 mm or 25 mm. Choose from three options regarding tool quality: Standard, hardened or premium.

With the offline-software option on PROLINK W, programming can be completed in the office away from the machine.

6 outputs for ProLink W.

Prepared for robot. With robot you get a fully automatic production unit.

Includes one extra foot pedal to use on the folding side and a key switch to select between the two foot pedals. There is also a safety switch for ”up-bending only”. Floor scanner is set up with two areas, one small for folding side operation and one large for back gauge operation.

When working from the folding side, it is only possible to do up-bending.

Allows the operator to move the foot pedal quickly and smoothly along the folding area. Appropriate when folding is done with several folding stations. This option is considered a great safety feature when bolted to the floor. When operator engages foot pedal, they are away from the upcoming folding beam.

Vacuum gripper in the back gauge for semi-automation. The FORMA Z 3200 can be equipped with 6 or 10 vacuum grippers. The FORMA Z 4100 can be equipped with 8 or 12 vacuum grippers. The vaccum grippers are sectioned in groups and the groups can be controlled individually.