Products Flat sheet storage – Stackmaster

Flat sheet storage – Stackmaster

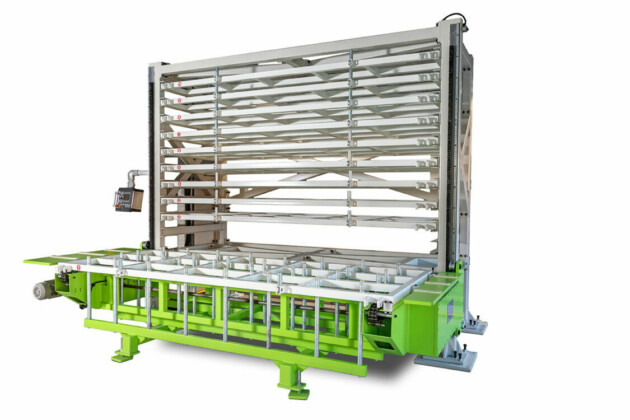

The tray transport drive system has 2 motors, one 5 kW motor to power the lifting of trays, and one 1.5 kW motor to power the sheet tray in and out of the STACKMASTER. The lifting drive is a dual rack and pinion design. While the sheet tray movement work with a sprocket and dual chain drive. A frequency drive insures smooth transmission of 10 m/min of lifting speed.

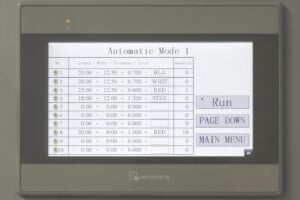

CIDAN STACKMASTER – flat sheet storage. Stackmaster meets your needs in 10, 15 or 20 tray high storage. The control system keeps track of different sizes, qualities and colors stored in the different trays. Choose desired material via the control panel and STACKMASTER delivers correct material. Then you just easily move the sheet to next working operation. Works perfectly well for them who only buys already cut flat sheets as well as for those who produces own flat sheets with a cut-to-length line. The CIDAN Stackmaster metal sheet storage gives you a good overview of your flat sheets inventory!

CIDAN STACKMASTER – flat sheet storage. Why do you need one?

Flexible & speedy – You have laser cut / punched blanks, low order quantities and short lead time requirements? A STACKMASTER close to your folding machine will do the trick!

Space-saving – Flat-sheet-bundles all over the place? Stack them high in a STACKMASTER, in a small place!

Good overview – With the control on the machine you keep track of all your sheets and they are all stored in one place, simple and precise inventory.

Your forklift for other things – You have a manual stacking tower, but need a forklift every time you need a bundle? A STACKMASTER only needs a forklift when you fill it up.

Ramping up… – You want to automize, but not kill yourself with investment? Ramp up, step-by-step. First folding machine, then add a STACKMASTER and finally a robot controlling both machines. No need going to a fully automatic line in one go…

CIDAN STACKMASTER metal sheet storage loads up to 3200 x 1500 mm sheets and comes in five models:

- 10 trays à 1000 kg, 3.2 m height

- 10 trays à 2000 kg, 3.6 m height

- 15 trays à 1000 kg, 4.2 m height

- 15 trays à 2000 kg, 4.8 m height

- 20 trays à 1000 kg, 5.2 m height

| Specifications | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Max load per tray | Number of trays | Max sheet size | Max loading height per tray | Lifting speed | Feeding speed trays | Height | Length | Depth | Lifting motor | Tray motor | Weight | |||||||||||||||||||||||||||||||||||||

| kg | pcs | mm | mm | m/min | m/min | mm | mm | mm | kW | kW | kg | ||||||||||||||||||||||||||||||||||||||

| RFT-3200×1500/10 | 1000 | 10 | 1500 x 3200 | 100 | 10 | 9 | 3200 | 3600 | 4600 | 5 | 1.5 | 5900 | |||||||||||||||||||||||||||||||||||||

| RFT-3200×1500/15 | 1000 | 15 | 1500 x 3200 | 100 | 10 | 9 | 4200 | 3600 | 4600 | 5 | 1.5 | 8300 | |||||||||||||||||||||||||||||||||||||

| RTF-3200×1500/20 | 1000 | 20 | 1500 x 3200 | 100 | 10 | 9 | 5200 | 3600 | 4600 | 5 | 1.5 | 10200 | |||||||||||||||||||||||||||||||||||||

| RTF-3200×1500/10 2T | 2000 | 10 | 1500 x 3200 | 120 | 10 | 9 | 3620 | 3600 | 4600 | 7 | 1.5 | 8000 | |||||||||||||||||||||||||||||||||||||

| RTF-3200×1500/15 2T | 2000 | 15 | 1500 x 3200 | 120 | 10 | 9 | 4820 | 3600 | 4600 | 7 | 1.5 | 10000 | |||||||||||||||||||||||||||||||||||||

Other sizes available in request.

- 10 trays

- Max load 1000 kg per tray

- Up to 3200 mm long sheets

- Creates better structure of flat sheets

- Easy handling of flat sheets

- Eliminates heavy lifting

- Increases the control of inventory

- Up to 20 trays

- Max 2000 kg per tray

- Up to 4400 mm long sheets

- Creates better structure of flat sheets

- Eliminates heavy lifting